Mechanical properties and microstructure of cranial and beak bones of the woodpecker and the lark

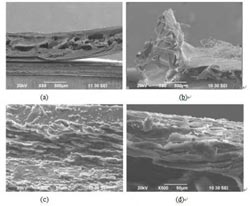

These are SEM images of the cranial bone and beak bone of the great spotted woodpecker and the lark Cranial bone of (a) woodpecker and (b) lark; beak of (c) woodpecker and (d) lark. Credit: © Science China Press<br>

Professor FAN Yubo and his group from the Key Laboratory for Biomechanics and Mechanobiology of the Ministry of Education, School of Biological Science and Medical Engineering, Beihang University, and the School of Materials Science and Engineering, Wuhan University of Technology, set out to study this problem.

After 3 years of innovative research, they are making progress in uncovering the explanation for the avoidance of head impact injury by woodpeckers. Their work, entitled “Comparative study of the mechanical properties, micro-structure, and composition of the cranial and beak bones of the great spotted woodpecker and the lark bird”, was published in SCIENCE CHINA Life Sciences, 2011, Vol. 54 (11).

Head injury, caused by a sudden impact or by a change in the linear or angular velocity of the head, is a leading cause of morbidity and death in both industrialized and developing countries. It is estimated that brain injuries account for 15% of the overall burden of fatalities and disabilities and are the leading cause of death in young adults. Woodpeckers clearly are adapted to managing impact forces, allowing them to peck rapidly without incurring brain or eye injury. This ability has attracted wide attention not only by ornithologists and biologists but also by researchers in the mechanical and electronic sciences. Previous studies suggested that impact injury to the brain might be avoided by powerful muscles, or by drilling behavior, or by a special orientation of the brain within the skull compared with humans. However, there have been few systematic analyses of the properties of woodpecker's skull.

Therefore, to understand how woodpeckers are adapted to pecking at high-speeds and frequency, the group carried out a comparative study of the mechanical properties, microstructure and composition of the cranial bone and beak of this bird, which represent remarkable examples of nanofabrication and self-assembly, perfected by natural evolution over millions of years.

The ultimate strength of woodpecker's cranial bone was found to be markedly higher than that of the lark. In contrast, there was no significant difference between the two birds in the ultimate strengths of their beaks. More plate-like spongy bone was present in the cranial bone of the woodpecker, while the cranium of the lark contained more rod-like structures. It appears that the mechanical properties and microstructure are closely linked. The larger number of plate-like structures, greater thickness and numbers of trabeculae, and the closer spacing between individual trabeculae in the woodpecker cranial bone would tend to resist deformation during pecking, which would decrease the stress on the brain. Conversely, the greater quantity of rod-like structures and thinner trabeculae of the woodpecker's beak would lead to greater deformation during impact. As the impact load is absorbed and distributed primarily by the beak, its transmission to the brain would be decreased. Together these parameters combine to produce quite similar ultimate strengths of the beaks of the woodpecker and the lark.

It was concluded that, compared with the lark, the cranial bone of the woodpecker achieves a higher ultimate strength and resistance to impact injury as a result of its unique microstructure, including more plate-like trabecular bone, greater thickness, greater numbers and closer spacing of trabeculae, and a higher proportion of bone mineral. These distinctive mechanical and structural properties, and compositions, of the cranial and beak bones of the woodpecker provide excellent resistance to head impact injury at a high speed and deceleration. Such information may perhaps inspire the design and optimization of protective headgear for humans.

See the article: WANG L Z, ZHANG H Q, and FAN Y B. Comparative study of the mechanical properties, micro-structure, and composition of the cranial and beak bones of the great spotted woodpecker and the lark bird. SCI CHINA Life Sci, 2011, 54(11):1036-1041.

Media Contact

More Information:

http://www.buaa.edu.cnAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…