Laser light produces synthetic tissue for regenerative medicine

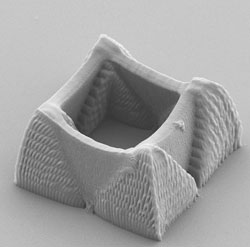

Test matrix consisting of a polymer support structure and a protein functional structure. Fraunhofer Institute for Laser Technology ILT, Aachen<br>

So that tissue can be produced to replicate the body’s natural tissue, knowledge of the interaction between cells in a three-dimensional framework and the growth conditions for complete regeneration is essential. Using a special laser technique, research scientists at the Fraunhofer Institute for Laser Technology ILT and other Fraunhofer Institutes have succeeded in producing hybrid biomimetic matrices. These serve as a basis for scaffold and implant structures on which the cells can grow effectively.

If tissue has been badly damaged by disease or due to an accident or if parts of the tissue have been completely removed, the body is often unable to regenerate this tissue itself. What’s more, in many cases no endogenous material is available for transplants. As a result, demand in the medical field is increasing for implants which enable complete regeneration to take place. But the current artificially produced implants are often not adequately adapted to the environment in the patient’s body and are therefore of limited use as a tissue replacement. The main reason for this lack is the missing knowledge on how cells react to a threedimensional environment. Scientists at Fraunhofer ILT in cooperation with other Fraunhofer Institutes, however, have developed a process for producing biomimetic scaffolds which closely emulates the endogenous tissue.

This process allows the fabrication of specialized model systems for the study of threedimensional cell growth, for the future generation of optimal conditions for the cells to colonize and grow. For this purpose the Aachen-based research scientists have transferred the rapid prototyping technique to endogenous materials. They combine organic substances with polymers and produce three-dimensional structures which are suitable for building artificial tissue.

Laser light converts liquid into 3-D solids

As the basis the research scientists use dissolved proteins and polymers which are irradiated with laser light and crosslinked by photolytic processes. For this they deploy specially developed laser systems which by means of ultra-short laser pulses trigger multiphoton processes that lead to polymerization in the volume. In contrast to conventional processes, innovative and low-cost microchip lasers with pulse durations in the picosecond range are used at Fraunhofer ILT which render the technique affordable for any laboratory. The key factors in the process are the extremely short pulse durations and the high laser-beam intensities. The short pulse duration leads to almost no damage by heat to the material. Ultra-fast pulses in the megawatt range drive a massive amount of protons into the laser focus in an extremely short time, triggering a non-linear effect. The molecules in the liquid absorb several photons simultaneously, causing free radicals to form which trigger a chemical reaction between the surrounding molecules. As a result of this process of multiphoton polymerization, solids form from the liquid. On the basis of CAD data the system controls the position of the laser beam through a microscope with a precision of a few hundred nanometers in such a way that micrometer-fine, stable volume elements of crosslinked material gradually form.

»This enables us to produce scaffolds for cell scaffolds with a resolution of approximately one micrometer directly from dissolved proteins and polymers to exactly match our construction plan,« explains Sascha Engelhardt, project manager at the ILT. »These biomimetic scaffolds will enable us to answer many aspects of threedimensional cell growth.« For this purpose the team of research scientists uses various endogenous proteins, such as albumin, collagen and fibronectin. As pure protein structures are not very shape-stable, however, the Aachen-based researchers combine them with biocompatible polymers. These polymers are used to generate a scaffold which in a subsequent step provides a framework for the protein structures that have been produced. This new process makes it possible to create structures offering much greater stability. The scaffold can be seeded with the patient’s own cells in a medical laboratory. The colonized scaffolds can then be expected to produce good implant growth in the patient’s body. The long-term aim is to use the process to produce not only individual cell colonies but also complete artificial tailor-made organs. That would represent a huge medical advance!

The Fraunhofer ILT research scientists are currently engaged in work to optimize the process. For example, they want to greatly increase the production speed by combining the fabrication process with other rapid prototyping methods, in order to reduce the time and cost involved in producing tailor-made supporting structures for synthetic tissue.

Contacts at Fraunhofer ILT

Our experts will be pleased to assist if you have any questions:

Dipl.-Phys. Sascha Engelhardt

Biotechnology and Laser Therapy

Phone +49 241 8906-605

sascha.engelhardt@ilt.fraunhofer.de

Dr. Martin Wehner

Biotechnology and Laser Therapy

Phone +49 241 8906-202

martin.wehner@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen

Phone +49 241 8906-0

Fax +49 241 8906-121

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…