DNA nano-foundries cast custom-shaped metal nanoparticles

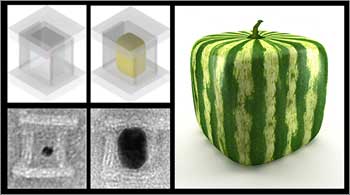

The concept of casting nanoparticles inside DNA molds is very much alike the Japanese method of growing watermelons inside cube-shaped glass boxes. Credit: Harvard's Wyss Institute / Peng Yin

Researchers at the Wyss Institute for Biologically Inspired Engineering at Harvard University have unveiled a new method to form tiny 3D metal nanoparticles in prescribed shapes and dimensions using DNA, Nature's building block, as a construction mold.

The ability to mold inorganic nanoparticles out of materials such as gold and silver in precisely designed 3D shapes is a significant breakthrough that has the potential to advance laser technology, microscopy, solar cells, electronics, environmental testing, disease detection and more.

“We built tiny foundries made of stiff DNA to fabricate metal nanoparticles in exact three–dimensional shapes that we digitally planned and designed,” said Peng Yin, senior author of the paper, Wyss Core Faculty member and Assistant Professor of Systems Biology at Harvard Medical School.

The Wyss team's findings, described in a paper titled “Casting Inorganic Structures with DNA Molds,” were published today in Science. The work was done in collaboration with MIT's Laboratory for Computational Biology and Biophysics, led by Mark Bathe, senior co–author of the paper.

“The paper's findings describe a significant advance in DNA nanotechnology as well as in inorganic nanoparticle synthesis,” Yin said. For the very first time, a general strategy to manufacture inorganic nanoparticles with user-specified 3D shapes has been achieved to produce particles as small as 25 nanometers or less, with remarkable precision (less than 5 nanometers). A sheet of paper is approximately 100,000 nanometers thick.

The 3D inorganic nanoparticles are first conceived and meticulously planned using computer design software. Using the software, the researchers design three–dimensional “frameworks” of the desired size and shape built from linear DNA sequences, which attract and bind to one another in a predictable manner.

“Over the years, scientists have been very successful at making complex 3D shapes from DNA using diverse strategies,” said Wei Sun, a postdoctoral scholar in the Wyss' Molecular Systems Lab and the lead author of the paper. For example, in 2012, the Wyss team revealed how computer-aided design could be used to construct hundreds of different self–assembling one–, two–, and three–dimensional DNA nanoshapes with perfect accuracy. It is this ability to design arbitrary nanostructures using DNA manipulation that inspired the Wyss team to envision using these DNA structures as practical foundries, or “molds”, for inorganic substances.

“The challenge was to translate this kind of 3D geometrical control into the ability to cast structures in other diverse and functionally–relevant materials, such as gold and silver,” Sun said.

Just as any expanding material can be shaped inside a mold to take on a defined 3D form, the Wyss team set out to grow inorganic particles within the confined hollow spaces of stiff DNA nanostructures.

The concept can be likened to the Japanese method of growing watermelons in glass cubes. By nurturing watermelon seeds to maturity inside cube–shaped glass boxes, Japanese farmers create cube-shaped mature melons that allow for densely–packed shipping and storage of the fruit.

The Wyss researchers similarly planted a miniscule gold “seed” inside the hollow cavity of their carefully designed cube–shaped DNA mold and then stimulated it to grow. Using an activating chemical solution, the gold seed grew and expanded to fill all existing space within the DNA framework, resulting in a cuboid nanoparticle with the same dimensions as its mold, with the length, width and height of the particle able to be controlled independently.

Next, researchers fabricated varied 3D polygonal shapes, spheres, and more ambitious structures, such as a 3D Y–shaped nanoparticle and another structure comprising a cuboid shape sandwiched between two spheres, proving that structurally–diverse nanoparticles could be shaped using complex DNA mold designs.

Given their unthinkably small size, it may come as a surprise that stiff DNA molds are proportionally quite robust and strong, able to withstand the pressures of expanding inorganic materials. Although the team selected gold seedlings to cast their nanoparticles, there is a wide range of inorganic nanoparticles that can be forcibly shaped through this process of DNA nanocasting.

A very useful property is that once cast, these nanoparticles can retain the framework of the DNA mold as an outer coating, enabling additional surface modification with impressive nanoscale precision. These coatings can also help scientists develop highly-sensitive, multiplex methods of detecting early–stage cancers and genetic diseases by combining the chemical specificity of the DNA with the signal readout of the metal. For particles that would better serve their purpose by being as electrically conducive as possible, such as in very small nanocomputers and electronic circuitry, the DNA framework coating is quickly and easily broken down and removed to produce pure metal wires and connectors.

“The properties of DNA that allow it to self assemble and encode the building blocks of life have been harnessed, re–purposed and re–imagined for the nano–manufacturing of inorganic materials,” said Don Ingber, Wyss Institute founding director. “This capability should open up entirely new strategies for fields ranging from computer miniaturization to energy and pathogen detection.”

MEDIA CONTACT

Wyss Institute for Biologically Inspired Engineering at Harvard University

Kat J. McAlpine, katherine.mcalpine@wyss.harvard.edu, +1 617-432-8266

About the Wyss Institute for Biologically Inspired Engineering at Harvard University

The Wyss Institute for Biologically Inspired Engineering at Harvard University (http://wyss.harvard.edu) uses Nature's design principles to develop bioinspired materials and devices that will transform medicine and create a more sustainable world. Working as an alliance among all of Harvard's Schools, and in partnership with Beth Israel Deaconess Medical Center, Brigham and Women's Hospital, Boston Children's Hospital, Dana Farber Cancer Institute, Massachusetts General Hospital, the University of Massachusetts Medical School, Spaulding Rehabilitation Hospital, Boston University, Tufts University, and Charité – Universitätsmedizin Berlin, and the University of Zurich, the Institute crosses disciplinary and institutional barriers to engage in high-risk research that leads to transformative technological breakthroughs. By emulating Nature's principles for self-organizing and self-regulating, Wyss researchers are developing innovative new engineering solutions for healthcare, energy, architecture, robotics, and manufacturing. These technologies are translated into commercial products and therapies through collaborations with clinical investigators, corporate alliances, and new start-ups.

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…