Brown University chemists simplify biodiesel conversion

As the United States seeks to lessen its reliance on foreign oil, biodiesel is expected to play a role. According to the National Renewable Energy Laboratory, a branch of the Department of Energy, biodiesel “represents a significant energy resource and could someday supply 3 percent to 5 percent of the distillate fuel market.”

One major obstacle to achieving that goal is figuring how to efficiently convert the abundant stocks of waste vegetable oil (oil used after cooking French fries, for example) into biodiesel fuel. Current techniques take time, are costly and are inefficient. Worse, the conversion requires the toxic chemicals sulfuric acid and either potassium hydroxide or sodium hydroxide.

That’s where Brown University chemist Jason Sello and postdoctoral researcher Aaron Socha come in. They write in the journal Organic & Biomolecular Chemistry that they were able to convert waste vegetable oil to biodiesel in a single reaction vessel using environmentally friendly catalysts. Their process is also six times faster than current methods for converting waste vegetable oil to biodiesel, so it consumes less energy.

“We wanted to develop an environmentally benign and technically simple way to convert waste vegetable oil into biodiesel,” said Sello, assistant professor of chemistry. “The production of energy at the expense of the environment is untenable and should be avoided at all costs.”

Waste vegetable oil is made up of triacylglycerols, free fatty acids, and water. The conventional way to convert waste vegetable oil into biodiesel requires two separate reactions. The first reaction turns the free fatty acids into biodiesel, but that conversion requires sulfuric acid. The second reaction converts the triacylglycerols into biodiesel, but that conversion requires sodium hydroxide or potassium hydroxide. Sodium hydroxide/potassium hydroxide and sulfuric acid are not compatible with each other, so the reactions must be carried out in separate vessels. That makes the process less efficient.

To find a better way, Sello and Socha went looking for catalysts that would be cheap, chemically stable and of limited toxicity. They settled on the metals bismuth triflate and scandium triflate, commonly used as catalysts in preparative organic chemistry. In addition, they performed the reactions using a microwave reactor instead of a conventional thermal heater. What they found was the new catalysts converted waste vegetable oil into biodiesel in about 20 minutes in the microwave reactor, whereas current reactions without catalysts using a conventional heater take two hours. While their microwave method needs a higher temperature to pull off the biodiesel conversion — 150 degrees Celsius versus 60 degrees Celsius under current methods — it uses less energy overall because the reaction time is much shorter.

The chemists also were able to perform the conversion in one reaction vessel, since the catalysts can promote both the reaction that converts free fatty acids into biodiesel and the reaction in which triacylgycerols are converted to biodiesel.

The team also reports that the catalysts in the free fatty acid conversion, which is the more challenging of the two reactions, could be recycled up to five times, while maintaining the capacity to promote a 97 percent reaction yield. The fact the catalysts can be recycled lowers their cost and environmental impact, the researchers said.

“While we have not yet proven the viability of our approach on an industrial scale,” Sello said, “we have identified very promising catalysts and reaction conditions that could, in principle, be used for large-scale conversion of waste vegetable oil into biodiesel in an enviornmentally sensitive manner.”

The research was funded by the National Science Foundation through a grant to Sello and an American Competitiveness in Chemistry award to Socha. Brown also supported the work through a R.B. Salomon award to Sello.

In a separate yet related paper, a team led by Brown chemistry professor Paul Williard has created a new technique to chart the progress of a reaction in which virgin oils are converted into biodiesel fuel.

The technique, called DOSY (for diffusion-ordered nuclear magnetic resonance spectroscopy), observes virgin oil molecules as they shrink in size and move faster in solution during the reaction. The reaction is complete when all of the molecules have been converted into smaller components known as fatty acid esters. These fatty acid esters are used as biodiesel fuel.

The results are published in the journal Energy & Fuels. The research was funded by the National Science Foundation. Contributing authors include Sello, Socha, Brown graduate students Gerald Kagan and Weibin Li, and lab technician Russell Hopson.

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…

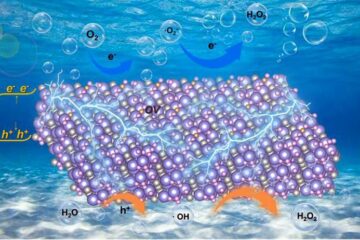

Oxygen vacancies mediated ultrathin Bi4O5Br2 nanosheets

… as efficient piezocatalyst for synthesis of H2O2 from pure water. As an important chemical raw material, hydrogen peroxide (H2O2) is widely applied in various aspects of industry and life….

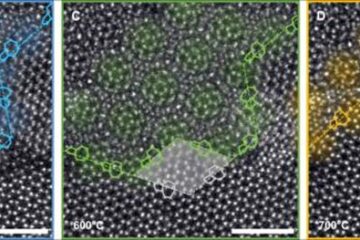

Atom-by-atom: Imaging structural transformations in 2D materials

Silicon-based electronics are approaching their physical limitations and new materials are needed to keep up with current technological demands. Two-dimensional (2D) materials have a rich array of properties, including superconductivity…