Bone marrow-on-a-chip unveiled

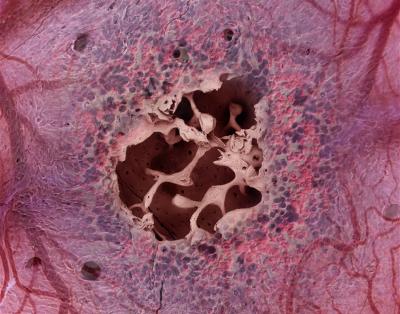

This is a microscopic view of the engineered bone with an opening exposing the internal trabecular bony network, overlaid with colored images of blood cells and a supportive vascular network that fill the open spaces in the bone marrow-on-a-chip. Credit: James Weaver, Harvard's Wyss Institute

The latest organ-on-a-chip from Harvard's Wyss Institute for Biologically Inspired Engineering reproduces the structure, functions and cellular make-up of bone marrow, a complex tissue that until now could only be studied intact in living animals, Institute researchers report in the May 4, 2014, online issue of Nature Methods. The device, dubbed “bone marrow-on-a-chip,” gives scientists a much-needed new tool to test the effects of new drugs and toxic agents on whole bone marrow.

Specifically, the device could be used to develop safe and effective strategies to prevent or treat radiation's lethal effects on bone marrow without resorting to animal testing, a challenge being pursued at the Institute with funding from the U.S. Food and Drug Administration (FDA). In an initial test, the engineered bone marrow, like human marrow, withered in response to radiation unless a drug known to prevent radiation poisoning was present.

The bone marrow-on-a-chip could also be used in the future to maintain a cancer patient's own marrow temporarily while he or she underwent marrow-damaging treatments such as radiation therapy or high-dose chemotherapy.

“Bone marrow is an incredibly complex organ that is responsible for producing all of the blood cell types in our body, and our bone marrow chips are able to recapitulate this complexity in its entirety and maintain it in a functional form in vitro,” said Don Ingber, M.D., Ph.D., Founding Director of the Wyss Institute, Judah Folkman Professor of Vascular Biology at Harvard Medical School and Boston Children's Hospital, Professor of Bioengineering at the Harvard School of Engineering and Applied Sciences, and senior author of the paper.

Ingber leads a large effort to develop human organs-on-chips — small microfluidic devices that mimic the physiology of living organs. So far Wyss Institute teams have built lung, heart, kidney, and gut chips that reproduce key aspects of organ function, and they have more organs-on-chips in the works. The technology has been recognized internationally for its potential to replace animal testing of new drugs and environmental toxins, and as a new way for scientists to model human disease.

To build organ chips, in the past Wyss teams have combined multiple types of cells from an organ on a plastic microfluidic device, while steadily supplying nutrients, removing waste, and applying mechanical forces the tissues would face in the body. But bone marrow is so complex that they needed a new approach to mimic organ function.

This complexity arises because bone marrow has an integral relationship with bone. Marrow sits inside trabecular bone — a solid-looking type of bone with a porous, honeycombed interior. Throughout the honeycomb, conditions vary. Some areas are warmer, some cooler; some are oxygen-rich, others oxygen-starved, and the dozen or so cell types each have their own preferred spots. To add complexity, bone marrow cells communicate with each other by secreting and sensing a variety of biomolecules, which act locally to tell them whether to live, die, specialize or multiply.

Rather than trying to reproduce such a complex structure cell by cell, the researchers enlisted mice to do it.

“We figured, why not allow Mother Nature to help us build what she already knows how to build,” said Catherine S. Spina, an M.D.-Ph.D. candidate at Boston University, researcher at the Wyss Institute, and co-lead author of the paper.

Specifically, Wyss Institute Postdoctoral Fellow Yu-suke Torisawa and Spina packed dried bone powder into an open, ring-shaped mold the size of a coin battery, and implanted the mold under the skin on the animal's back.

After eight weeks, they surgically removed the disk-shaped bone that had formed in the mold and examined it with a specialized CAT scanner. The scan showed a honeycomb-like structure that looked identical to natural trabecular bone.

The marrow looked like the real thing as well. When they stained the tissue and examined it under a microscope, the marrow was packed with blood cells, just like marrow from a living mouse. And when the researchers sorted the bone marrow cells by type and tallied their numbers, the mix of different types of blood and immune cells in the engineered bone marrow was identical to that in a mouse thighbone.

To sustain the engineered bone marrow outside of a living animal, the researchers surgically removed the engineered bone from mice, then placed it in a microfluidic device that mimics the circulation the tissue would experience in the body.

Marrow in the device remained healthy for up to one week. This is long enough, typically, to test the toxicity and effectiveness of a new drug.

The device also passed an initial test of its drug-testing capabilities. Like marrow from live mice, this engineered marrow was also susceptible to radiation — but an FDA-approved drug that protects irradiated patients also protected the marrow on the chip.

In the future, the researchers could potentially grow human bone marrow in immune-deficient mice. “This could be developed into an easy-to-use screening-based system that's personalized for individual patients,” said coauthor James Collins, Ph.D., a Core Faculty member at the Wyss Institute and the William F. Warren Distinguished Professor at Boston University, where he leads the Center of Synthetic Biology.

Bone marrow-on-a-chip could also generate blood cells, which could circulate in an artificial circulatory system to supply a network of other organs-on-chips. The Defense Agency Advanced Research Projects Agency (DARPA) is funding efforts at the Wyss Institute to develop an interconnected network of ten organs-on-chips to study complex human physiology outside the body.

The work was funded by the U.S. Food and Drug Administration, DARPA, and the Wyss Institute for Biologically Inspired Engineering at Harvard University. In addition to Ingber, Torisawa, Spina and Collins, the authors included Tadanori Mammoto, Ph.D. and Akiko Mammoto, Ph.D., Instructors in Surgery at Boston Children's Hospital and Harvard Medical School, James Weaver, Ph.D., a Research Associate at the Wyss Institute, and Tracy Tat, a Research Technician at Boston Children's Hospital.

PRESS CONTACTS

Wyss Institute for Biologically Inspired Engineering at Harvard University

Dan Ferber

dan.ferber@wyss.harvard.edu

+1 617-432-1547

Boston University College of Engineering

Michael Seele

mseele@bu.edu

+1 617-353-9766

Harvard School of Engineering and Applied Sciences

Caroline Perry

cperry@seas.harvard.edu

+1 617-496-1351

IMAGES AND VIDEO AVAILABLE

About the Wyss Institute for Biologically Inspired Engineering at Harvard University

The Wyss Institute for Biologically Inspired Engineering at Harvard University uses Nature's design principles to develop bioinspired materials and devices that will transform medicine and create a more sustainable world. Working as an alliance among Harvard's Schools of Medicine, Engineering, and Arts & Sciences, and in partnership with Beth Israel Deaconess Medical Center, Brigham and Women's Hospital, Boston Children's Hospital, Dana Farber Cancer Institute, Massachusetts General Hospital, the University of Massachusetts Medical School, Spaulding Rehabilitation Hospital, Boston University, Tufts University, and Charité – Universitätsmedizin Berlin, the Institute crosses disciplinary and institutional barriers to engage in high-risk research that leads to transformative technological breakthroughs. By emulating Nature's principles for self-organizing and self-regulating, Wyss researchers are developing innovative new engineering solutions for healthcare, energy, architecture, robotics, and manufacturing. These technologies are translated into commercial products and therapies through collaborations with clinical investigators, corporate alliances, and new start-ups.

The Boston University College of Engineering offers a wide range of undergraduate, graduate and professional degrees in foundational and emerging engineering disciplines. Underlying the College's educational efforts is its commitment to creating Societal Engineers, who have an appreciation for how the engineer's unique skills can be used to improve our quality of life. Ranked among the nation's best engineering research institutions, the College's faculty attracts more than $50 million in external research support annually.

About the Harvard School of Engineering and Applied Sciences

The Harvard School of Engineering and Applied Sciences (SEAS) serves as the connector and integrator of Harvard's teaching and research efforts in engineering, applied sciences, and technology. Through collaboration with researchers from all parts of Harvard, other universities, and corporate and foundational partners, we bring discovery and innovation directly to bear on improving human life and society. For more information, visit: http://seas.harvard.edu.

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…