Sustainable ways to keep us flying

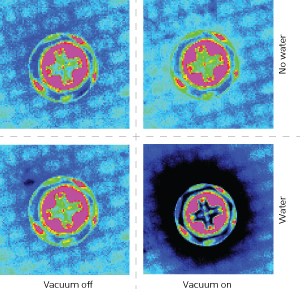

Building the future of flight - Dmitry Isakov at A*STAR is investigating the infiltration of water under the surface of an aircraft by applying a vacuum to a bolt head. Thermal imaging reveals a cooler area around the bolt head when the vacuum is switched on (bottom right) that indicates the presence of water, which is not seen in a dry bolt head (top right). Copyright : 2014 A*STAR Singapore Institute of Manufacturing Technology

The global aviation industry continues to expand, with over 3 billion people expected to fly commercially in 2014, along with 38 million metric tons of cargo. This activity will have a huge impact on the environment and requires vast resources. In order to make air travel a sustainable option for future generations, the industry needs to perform continual research into technologies that reduce both economic and environmental costs.

The A*STAR Aerospace Programme was set up to combine the efforts of A*STAR researchers who are striving to provide a sustainable future for aviation. Since 2007, scientists from several A*STAR research institutes have worked together on over 50 multidisciplinary projects to pioneer manufacturing techniques, safety inspection devices and analytical methods to improve flight management. To highlight this success, their work was showcased earlier this year at the Singapore Airshow 2014.

Finding faults faster

Aircraft will always experience wear and tear, and A*STAR researchers are developing fast, cost-effective methods to identify parts in need of repair. Crucially, these methods aim to be non-destructive, which means that fewer parts need to be removed or replaced during inspection, saving both time and money.

One major problem for the industry is the infiltration of water into the aircraft body, especially in the lightweight honeycomb structures found in the tail and wings. Dmitry Isakov from the A*STAR Singapore Institute of Manufacturing Technology (SIMTech) is leading efforts to help technicians spot exactly where the water is.

“Water always finds the easiest way to get in, which is around discontinuities such as joints and bolts,” says Isakov. “Once inside, the water expands and contracts as it freezes and melts, damaging structures, causing corrosion and increasing the aircraft’s weight.”

To identify areas where water has entered, technicians currently heat the aircraft surface and then use thermal cameras to observe its cooling. Regions that cool too quickly indicate the presence of water below the surface. The method requires two engineers, is slow and cannot distinguish between water and excess sealant left behind after repairs.

Isakov has developed an alternative approach. “When a vacuum is created around a bolt head, water can boil even at room temperature,” he explains. Boiling consumes heat, causing the material around the water to cool down by as much as several degrees. “Water detection using my vacuum method requires just one technician, is fast and highly sensitive, and there is no ambiguity with the sealant,” Isakov adds.

In addition to improving fault detection, researchers at A*STAR are providing new methods for repairing damaged aircraft parts or manufacturing new designs. One promising technology under development is laser-aided additive manufacturing (LAAM) (see Laying the groundwork for a manufacturing revolution). This method, an example of three-dimensional printing technology, uses a high-energy laser beam to deposit materials in precisely controlled geometric structures or to fill in cracks. The ‘bottom-up’ approach is less wasteful than traditional methods that involve cutting components out of larger chunks of material.

“LAAM can repair or fabricate parts with excellent mechanical properties and resistance to wear and corrosion,” says Guijun Bi, a leading researcher at SIMTech. Bi is adapting LAAM techniques to build and repair structures using so-called superalloys, which maintain their strength even under the extreme conditions of a working jet engine.

The precise control provided by LAAM is enabling Bi and his co-workers to re-use components that would previously have been impossible or very costly to repair. The ‘remanufacturing’ of components is central to the aims of the A*STAR Aerospace Programme and provides clear environmental benefits through reducing resource consumption.

Keeping problems at bay

Other high-tech maintenance tools being developed at SIMTech include a system that uses electromagnetic waves to detect slight variations in the thickness or composition of components that may be the result of corrosion. Further monitoring can be provided by using piezoelectric sensors that ‘hear’ structural failures in real time, with the added benefit of turning the mechanical energy of the aircraft body into electricity.

The lifetime of aircraft components can be greatly extended by applying advanced water- and ice-repellent — ‘superhydrophobic’ — coatings developed at SIMTech that protect parts from condensation, corrosion and mold, as well as improving aerodynamics to reduce fuel consumption. Researchers are also pioneering the use of lasers, instead of expensive corrosive chemicals, to strip damaged coatings from turbines, allowing the parts to be re-used.

Aside from the development of inspection and remanufacturing tools, diverse expertise in computer simulation at A*STAR is providing novel ways to improve the experience of airline customers and staff.

Anyone who has flown will have heard the cabin crew asking passengers to switch off their electronic devices during take-off and landing because stray signals can interfere with flight systems. Now, researchers at the A*STAR Institute for Infocomm Research (I2R) have written simulations that identify the best way to arrange electronics on the aircraft for minimizing interference, enabling airlines to provide customers with wireless services without compromising safety. Another useful software developed at the I2R, named ‘Super De-haze’, provides pilots and air-traffic controllers with clearer imagery by removing the effects of haze, fog and smoke.

Finally, the complex challenge of airport management is being tackled by I2R researchers who have developed a flight prediction algorithm that captures the interactions of weather and flight congestion. Their algorithm won first prize in the GE Flight Quest 2013 challenge, estimating flight arrival times that were 40 per cent more accurate than current industry estimates. By applying similar models, airlines could achieve more efficient operation of gates and runways.

Flying ahead of the competition

The A*STAR Aerospace Programme is a prime example of the benefits of multidisciplinary research. The program is attracting interest from aviation giants and is set to ensure that Singapore maintains its competitive edge in the global aerospace marketplace.

More importantly, by improving aircraft design, maintenance, fuel economy and customer satisfaction, A*STAR is leading the way toward a more sustainable and environmentally friendly business model for aviation. Only through such long-sighted efforts will future generations continue to enjoy the many benefits of air travel.

About the Singapore Institute of Manufacturing Technology

The A*STAR Singapore Institute of Manufacturing Technology (SIMTech) develops high-value manufacturing technology and human capital to contribute to the competitiveness of Singapore’s industry. It collaborates with multinational and local companies in the precision engineering, electronics, semiconductor, medical technology, aerospace, automotive, marine, logistics and other sectors.

About the Institute for Infocomm Research

The Institute for Infocomm Research (I2R), Singapore’s largest information and communications technology research institute, is a member of the Agency for Science, Technology and Research (A*STAR) family. Established in 2002, the I2R’s vision is to power a vibrant and strong infocomm ecosystem in Singapore. The I2R focuses on conducting mission-oriented research to address key challenges faced locally. At the I2R, intelligence, communications and media (ICM) form three strategic thrusts. The institute’s research capabilities cover information technology, wireless and optical communication networks, interactive and digital media, sensors, signal processing and computing. The I2R performs research and development in ICM technologies to develop holistic solutions across the ICM value chain, believing that the greatest impact is created when research outcomes are translated into technologies that partners can readily deploy at a competitive advantage.

Media Contact

All latest news from the category: Interdisciplinary Research

News and developments from the field of interdisciplinary research.

Among other topics, you can find stimulating reports and articles related to microsystems, emotions research, futures research and stratospheric research.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…