Better turbine simulation software to yield better engines

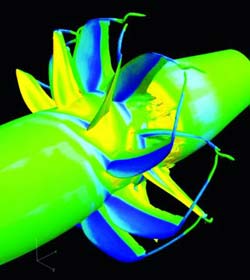

The research team of Jen-Ping Chen, Ph.D., associate professor of mechanical and aerospace engineering at the Ohio State University, used Ohio Supercomputer Center resources to create TURBO simulations for the flow field in an unducted counter-rotating fan. Credit: Chen/OSU<br>

For most of us, the word “turbomachinery” may conjure up images of superheroes or fast exotic cars, but in reality most people leverage turbomachinery to get things done nearly every day.

Turbomachinery – pumps, fans, compressors, turbines and other machines that transfer energy between a rotor and a fluid – is especially instrumental in power generation in the aeronautic, automotive, marine, space and industrial sectors. For engine designers to achieve the most efficient propulsion and power systems, they must understand the physics of very complex air-flow fields produced within multiple stages of constantly rotating rotors and stators.

Jen-Ping Chen, Ph.D., an associate professor of mechanical and aerospace engineering at The Ohio State University, is working to improve the computational fluid dynamics (CFD) software that engineers use to simulate and evaluate the operation of turbomachinery. Chen was the chief architect of that type of computer code, appropriately named TURBO, which he developed earlier for NASA.

Chen is leveraging the computational power of the Ohio Supercomputer Center to refine the software as it validates the flow field of engine components, specifically as it applies to high-pressure compressors and low-pressure turbines.

“The world is demanding increasingly cleaner, more efficient and reliable power systems,” noted Ashok Krishnamurthy, interim co-executive director of OSC. “Therefore, it is essential that experts like Dr. Chen find innovative ways to improve the tools the engineers need to accomplish that goal, and we at OSC are proud to be able to provide the computational resources that make that effort successful.”

Each turbomachinery component has unique physical characteristics that present difficulties in design and operation, such as stall in a compressor and cooling in a high-pressure turbine. With a simulation tool that is validated and optimized to run efficiently on a large computer cluster, engine designers will have more physical insight to the complex flow field, which will lead to reduced testing, reduced risk, faster time-to-market and lower costs.

While traditional wind-tunnel testing is often the most straightforward approach, it also comes with high costs and severe constraints on placing the measurement probes, according to Chen. Numerical simulation, using CFD, has provided an alternative for studying such flows at a lower cost and with unconstrained probe placement. Yet, the accuracy of a simulation depends on the accuracy of the mathematical model behind the simulation.

“Our goal is to develop a reliable prediction technology to help improve turbomachinery component design,” said Chen. “The successful combination of CFD simulation and experimentation can greatly supplement the understanding of fundamental fluid behavior of gas turbine systems, thus enhancing the ability of engineers to develop more advanced engine components.”

Chen's team is investigating three specific areas of current industrial interest: coupled fluid-structure interaction, active flow control and turbine film cooling. Improved numerical simulation will allow engineers to analyze complex flow fields and aeroelastic phenomena, such as flutter, limit-cycle oscillations, forced response, nonsynchronous vibrations and separated-flow vibrations, which arise from fluid-structure interaction.

Application of a newly developed flow control simulation model for vortex-generating jets in low-pressure turbines will help improve engineers' understanding of how flow control can be used to increase the performance and operability of gas turbine engines. And, finally, simulations can help engineers accurately predict the effectiveness of film cooling on heat transfer in a three-dimensional, unsteady, rotating environment with actual engine geometry.

Chen earned his doctorate and master's degree in aerospace engineering from Mississippi State University in 1991 and 1987, respectively, and his bachelor's degree in industrial engineering from Tunghai University in 1980. This study, “Numerical investigations of rotating components in air-breathing propulsion systems,” is funded through the Air Force Office of Scientific Research and N&R Engineering.

Media Contact

More Information:

http://www.osc.eduAll latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

Machine learning algorithm reveals long-theorized glass phase in crystal

Scientists have found evidence of an elusive, glassy phase of matter that emerges when a crystal’s perfect internal pattern is disrupted. X-ray technology and machine learning converge to shed light…

Mapping plant functional diversity from space

HKU ecologists revolutionize ecosystem monitoring with novel field-satellite integration. An international team of researchers, led by Professor Jin WU from the School of Biological Sciences at The University of Hong…

Inverters with constant full load capability

…enable an increase in the performance of electric drives. Overheating components significantly limit the performance of drivetrains in electric vehicles. Inverters in particular are subject to a high thermal load,…