Computer vision system detects foreign objects in processed poultry and food products

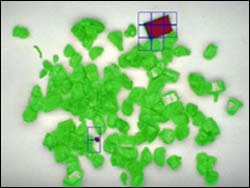

The squared segments indicate that the GTRI computer vision system’s software has detected a foreign object (in this case, plastic glove pieces) in the sample product. Photo Courtesy GTRI

Although metal detectors help commercial food processors keep metal fragments from ending up in finished products, these detectors can’t identify plastic and other foreign objects.

And as plastic becomes more widespread, used in everything from conveyor belts to latex gloves, plastic contamination is a growing concern for many food processing operations.

For the past year, John Stewart, a research engineer at the Georgia Tech Research Institute, has been leading a development team in building a computer-vision system that identifies plastic and other unwanted elements in finished food products. The project is funded by Georgia’s Traditional Industries Program for Food Processing with additional support from industrial partners.

The system, now in final development stages, is scheduled to begin field testing later this summer. Also, Stewart presented a paper on the project on July 18 at the American Society of Agricultural Engineers’ 2005 annual meeting in Tampa, Fla.

Incidences of plastic contamination are infrequent, but when they occur, fallout can be extensive. Recalls are expensive, not only in terms of logistics and returned product, but also because recalls can tarnish a company’s brand image and reduce consumer confidence.

Even if contamination is caught before a product leaves the factory, it can take a toll, depending on the extent of the problem and when it occurred. “When you have 6,000 to 8,000 pounds of poultry moving along the production line every hour, that’s a lot of chicken to reprocess or write-off,” Stewart said.

To help food processors ensure product quality, GTRI’s innovative inspection tool combines computer vision technology with sophisticated color discrimination algorithms. The computer-vision system, which sits above the production line adjacent to metal detectors, is first trained to identify the conveyor belt background and desired characteristics for the food product. This information is stored in the computer’s hard drive, and as the product moves along the conveyor, the computer-vision system captures digital pictures and analyzes them. If the system sees an object it doesn’t recognize, it records the digital image and activates an alarm and kick-off device that removes the product from the line.

Although this system can determine a full range of color, lab tests have focused on finding blue and green objects. Blue has become a standardized color for plastic used in the food processing environment. “Few foods are blue, so food processors hope that line workers will recognize any foreign objects making their way into the product stream,” Stewart explained.

Yet humans don’t make the most consistent inspectors. Although people are easily trained, they are also easily distracted, said GTRI research engineer Doug Britton, who is also working on the project.

“The product stream is moving very quickly – about 12 feet per second, which is the equivalent of eight miles per hour. If a person blinks or looks away for even a second, they can miss a problem,” Britton explained. “In contrast, machine vision is very diligent. It doesn’t get tired or bored.”

What’s more, line workers see only the top of finished products. GTRI’s computer-vision system captures additional views of surface area by taking digital images as products tumble off one conveyor belt and onto another.

“That doesn’t guarantee the system will spot every single incidence,” Stewart said. “Yet if it misses a fragment on one piece of product, it should stop subsequent products. The key is to pinpoint where contamination happened and how widespread it is.”

In lab tests, the system has been able to identify foreign objects as small as 1.5 millimeters with few false alarms and high accuracy rates (approaching 100 percent), researchers said. As the researchers begin field tests later this summer, one of their objectives is to see how well the system works in a real-world setting over a long period of time.

The system is designed to operate on conveyor belts moving 12 feet per second. In the lab, top conveyor speeds were 3 feet per second. But researchers simulated factory conditions by using dimmer lights and a longer integration time to produce blur.

The ultimate goal is to make the computer-vision system as fast and accurate as possible without outpricing the technology for industry users, researchers noted. To that end, GTRI has partnered with Gainco Inc., an equipment manufacturer in Gainesville, Ga. Gainco has provided feedback during the system’s development, and the company plans to make the production-scale system that will be used in field tests.

Though lab tests focused on finding plastic fragments in poultry products, GTRI’s computer-vision system also can identify non-plastic contaminants, such as glass, and be used for meat and other food products.

“We’re trying to make the system as generic as possible, so anything that doesn’t look like the product will be detected,” Stewart said.

Media Contact

More Information:

http://www.edi.gatech.eduAll latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…