Low-cost, digital displays through ink jet printing

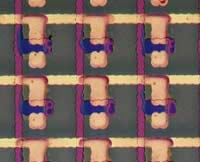

A grid of semiconductor polymer transistors jet-printed into a prototype circuit that can be used to control a flat panel display. <br>Image courtesy Palo Alto Research Center

Convergent technology is one thing – but using your computer’s printer to make a new TV screen?

Not quite, but close. In a breakthrough for low-cost electronics manufacturing, researchers at Palo Alto Research Center (PARC), a Xerox subsidiary, have successfully created a transistor array of the type used to control a flat-panel display using a modified ink-jet printer and semiconductor “ink.” Still under development, the technique is expected to dramatically lower the cost of the popular displays by replacing more expensive photolithography techniques that dominate display manufacturing. The new technology, co-funded by the National Institute of Standards and Technology (NIST), is expected to work on either rigid or flexible substrates, and could create whole new opportunities for wall-sized TV’s, unbreakable cell phone displays, computer displays that could roll up like a window shade and electronic paper.

PARC researchers used a new polymer-based semiconductor ink from Xerox Research Center Canada (XRCC) to build a prototype flat-panel display circuit. Transistor arrays are complex devices with multiple layers of conductors, insulators and semiconductors. Conventional photolithography uses a multistep process for each layer, first laying down the appropriate material, then creating a pattern for the components, and finally etching or transferring the pattern to the material. By contrast, PARC’s ink-jet process patterns and prints the components of each layer of the transistor array in one step. A key innovation, according to PARC, was a computer-vision system that ensures precise registration of each layer even if the substrate deforms slightly during the process.

The PARC research is part of a joint R&D partnership with Xerox, Motorola Inc. and Dow Chemical Company that is co-funded under NIST’s Advanced Technology Program (ATP). The semiconductor polymer ink also was developed under the ATP award.

Media Contact

All latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…