Detecting Chemical Threats With "Intelligent" Networks

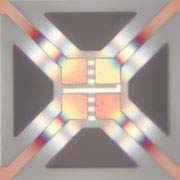

Micrograph of NIST sensor device used to detect toxic gases. Colors reflect slight variations in thickness of the sensing film. <br> <br>

Prototype microsensor arrays connected to artificial neural networks—computer models that “learn”—can reliably identify trace amounts of toxic gases in seconds, well before concentration levels become lethal, National Institute of Standards and Technology (NIST) scientists and a guest researcher reported Sept. 7 at the American Chemical Society annual meeting in New York City. The system has the potential to provide cost-effective early warning of chemical warfare agents.

Lab experiments show that the sensors, which use NIST-patented microheater technology, can detect compounds such as sulfur-mustard gas and nerve agents (tabun and sarin) at levels below 1 part per million. The neural networks, which currently run on a personal computer, were added recently to process signals from the sensor arrays. The networks enable the system to rapidly distinguish among the gases and predict their concentration in the ambient air.

The microheaters, which are coated with metal oxide films, can be programmed to cycle through a range of temperatures. Airborne chemicals attach to the film in characteristic ways depending on factors such as temperature and film material, causing changes in the flow of electricity through the microsensors. These changes serve as a “signature” for identifying both the type and concentration of the gas in the ambient air.

The neural networks were trained to detect subtle variations in these signatures. An array of four microheater sensors programmed to quickly sample 20 temperatures produces as much data as 80 different sensors.

Research is ongoing to more fully assess the impact of background interference as a means of avoiding false positives, and to enhance the robustness of the sensors with repeated use. The research is funded by NIST and the Defense Threat Reduction Agency.

Media Contact:

Laura Ost, (301) 975-4034

Media Contact

More Information:

http://www.nist.gov/public_affairs/techbeat/tb2003_0910.htmAll latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…