Powerful x|act: Software now available for GE´s phoenix High-Resolution X-ray Inspection Systems

phoenix x|act: Brilliant X-ray inspection images with informative live CAD data and inspection result overlay<br>

As Dr. Tobias Neubrand, product manager at phoenix|x-ray, explains: “The x|act software is available in three versions: x|act base, x|act operator and x|act pro. All versions offer easier operation than previous packages, allowing more reliable inspection. Simple macro recording permits intuitive programming of inspection tasks in terms of position and imaging parameters, with all display settings saved with just one mouse click. Automatically created sample maps can be used for all pcbs of the same type anywhere in the system, even when rotated and flipped, and automatic image enhancement improves live images to ensure greater precision of defect detection.”

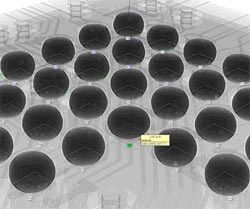

Additional software features included in the x|act operator upgrade package include the facility to introduce a live CAD data overlay, automated saving of results, images and X-ray sample maps and CAD-based programming. The pad IDs can be viewed in the live image as an overlay at any time and from any viewing angle. This always enables quick and precise solder joint mapping even with manual inspection. In addition to all the features of the first two versions, users who upgrade to x|act pro can enjoy CAD-based image processing as well as statistical review based on inspection results and 3D auto-referencing for optimized positioning accuracy to a few micrometers.

To keep programming time to a minimum, x|act operator and x|act pro import the CAD data of the pcb and create a model, which facilitates navigation and also enables inspection strategies to be assigned to the individual components to be inspected. Within x|act pro inspection strategies with all the information required for automatic inspection are contained in the library for many common solder joint types. After the inspection strategies have been assigned, the views required and inspection program are generated automatically. With CAD-based programming, all the programming steps can be performed offline at a separate workstation, meaning that the inspection system is not blocked during programming. It also means that programs can be transferred to every x|act-capable phoenix|x-ray system.

phoenix nanome|x and microme|x X-ray inspection systems feature an open 180 kV, 15 or 20 Watt nanofocus or microfocus X-ray tube optional with GE´s unique temperature stabilized DXR detector technology, which ensures brilliant live inspection images at 30 frames per second. 3D computed tomography (CT) scans of small electronic devices are also a possible option for advanced 3D failure analysis tasks.

GE Measurement & Control Solutions

GE Measurement & Control Solutions delivers accuracy, productivity and safety to a wide range of industries, including oil & gas, power generation, aerospace, transportation and healthcare. It has over 40 facilities in 25 countries.

Contact for readers' questions

GE Sensing & Inspection Technologies GmbH

Niels-Bohr-Str. 7

D-31515 Wunstorf

Tel.: +49 5031 172-0

phoenix-info@ge.com

Media Contact

Dr. Dirk Neuber | Beate Prüß

GE Sensing & Inspection Technologies GmbH

+49 5031 172-124 | -103

dirk.neuber@ge.com | beate.pruess@ge.com

Media Contact

All latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

Peptides on Interstellar Ice

A research team led by Dr Serge Krasnokutski from the Astrophysics Laboratory at the Max Planck Institute for Astronomy at the University of Jena had already demonstrated that simple peptides…

A new look at the consequences of light pollution

GAME 2024 begins its experiments in eight countries. Can artificial light at night harm marine algae and impair their important functions for coastal ecosystems? This year’s project of the training…

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…