Portable lab analysis – mini spectrometer integrated into your mobile phone

The novelty here are metallic nano-antennas for harvesting, filtering and amplifying of incoming photons. In addition, thin-film manufacturing technology makes this sensor affordable for mass production.

Spectrometers in a miniaturized size are required for many novel applications. For instance, approaching your smart-phone towards fruits and vegetables allows monitoring ripeness and freshness simply by quantifying the sugar content. Also a huge benefit for personalized medical care has been envisioned: people suffering e.g. from diabetes may track her/his blood sugar concentration through contact-free breath analysis. Furthermore, ultra-small spectrometers can be also relevant for security purposes, e.g. for toxic gas or liquid alarms.

Standard spectrometers so far are too bulky for the integration into compact electronic devices such as smart phones, simply because their physical principle reaches the uttermost size limits. Scientists at the Institute of Applied Photophysics (IAPP) at the »Technische Universität Dresden« and at the »Fraunhofer Institute for Electron Beam and Plasma Technology FEP« Dresden, are ready to make an innovation leap within the »nanoSPECS« project, funded by the German Ministry of Education and Science (BMBF).

With an absolutely new concept based on nano-antennas, the researchers will develop a mini-spectrometer that possesses a very high resolution and sensitivity throughout the full spectrum (from UV to near-infrared). But the most striking fact is that the »nanoSPECS« mini-spectrometer needs no movable parts at all for full operation.

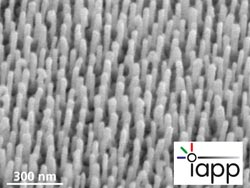

This »Dresden concept« is based on metallic nano-wires that act as tiny antennas for absorbing, amplifying and redirecting light to the detector, a CCD / CMOS chip that carries the antenna array. The sensing capabilities depend on the antennas length, diameter, material as well as the coupling distance between individual antennas, and hence can be tuned in order to reinforce specific wavelengths or wavelength ranges. The concept foresees to establish the antenna-arrays that show a gradient structure in one of the above-mentioned parameters covering the full electromagnetic spectrum with high amplification. The size of this novel spectrometer thus is solely limited by the size of a CCD / CMOS chip.

The IAPP has already developed a lab-scaled process to electrochemically grow such gold or silver nano-rod arrays into pores of an anodized aluminum-oxide matrix and has proven its variability and functionality. The main goal of the three-year »nanoSPECS« project, started in August 2013, is to manufacture and to up-scale such graded antenna-arrays to the 8”-wafer size. The challenge is to grow a precursor aluminum layer for anodization that shows a precise, reproducible and homogeneous thickness of expected micro-crystallinity. At this stage Fraunhofer FEP will apply its expertise in production of precision coatings through magnetron sputtering. This process ensures the high quality thin-film deposition needed for commercial production of mini-spectrometers for a large market.

Picture: What looks like a mini-carpet in the REM picture are gold nano-antennas of some 100 nm length and 30 nm diameter. These rods are sensitively absorbing visible light, filter photons, and finally concentrate and amplify selected wavelengths through plasmon resonances. These nanorod arrays form is the key element for modern-type optical sensors, as the stated goal within the »nanoSPECS« project.

»nanoSPECS« project is funded within the program »Validation of Innovation Potential of Science-VIP« of the Federal Ministry of Education and Research, Grant number: 03V0763

Press contact:

Annett Arnold

Fraunhofer-Institut für Elektronenstrahl- und Plasmatechnik FEP | Phone +49 351 2586 452 | Annett.Arnold@fep.fraunhofer.de

Winterbergstraße 28 | 01277 Dresden | Gemany | www.fep.fraunhofer.de

Media Contact

More Information:

http://www.fep.fraunhofer.deAll latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…