1st Conference on Laser Polishing LaP 2014

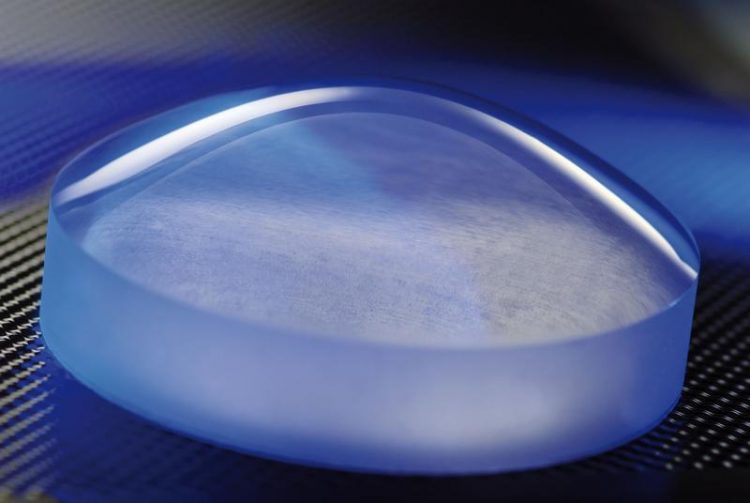

Laser-polished asphere Ø64 mm made from BK7. Source: Fraunhofer ILT, Aachen

Despite a steady increase in recent years in the number of working groups, publications and projects on the subject, laser polishing is still considered a niche technology.

This prompted Fraunhofer ILT to organize the 1st Conference on Laser Polishing LaP 2014 in Aachen, Germany. Headed by Dr. Edgar Willenborg, their event created an international platform for exchanging scientific findings in the laser polishing field. A total of 14 lectures were held in English, providing over 70 participants from 10 countries with the opportunity to gain a comprehensive picture of latest scientific developments and first industrial applications of laser polishing.

Industrial laser polishing

Dr. Thomas Kiedrowski (Robert Bosch GmbH) introduced a metal polishing application that is already in use today and with which millions of components are laser-polished annually. His presentation centered on an example taken from CVT production.

Two lectures given by Dr. Manyalibo Matthews (Lawrence Livermore National Laboratory) and Dr. Philippe Cormont (CEA CESTA) explained another way in which these new methods are being employed successfully, this being to repair optics for high-power laser systems by means of CO2 laser radiation.

Laser polishing equipment in action

In addition to the lectures, a further highlight for conference participants was a tour of the laboratories at Fraunhofer ILT that let them see the latest laser polishing machines and test set-ups. Among other things, visitors were shown a live demonstration of the adaptive laser polishing machine for the polishing of metal work pieces that was developed as part of the BMBF-funded ALPINE project.

The success of the 1st Conference on Laser Polishing – LaP 2014 reflects the great interest the scientific and industrial communities have in this new manufacturing process. There is clearly a significant demand for a cost-effective, automated finishing process that offers an alternative to conventional abrasive methods. This demand will continue to drive research in this area in the future, so we can expect more exciting developments in the field of laser polishing to be unveiled at the 2nd Conference on Laser Polishing – LaP 2016 from April 26-27, 2016 in Aachen.

Contact

Dr. Edgar Willenborg

Leader Polishing Group

Phone +49 241 8906-213

edgar.willenborg@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany

Media Contact

All latest news from the category: Event News

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…