Researchers close in on natural solution to PCB contamination

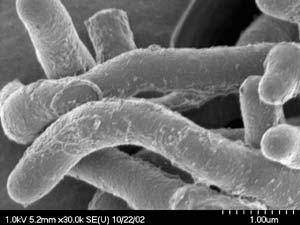

A micrograph image of Rhodococcus sp. RHA1, which are good PCB-degraders. Researchers Jeffrey Bolin and Lindsay Eltis hope bacteria, such as these, can be bred to digest PCBs effectively enough to cleanse the environment of these hazardous chemicals. (Photo/UBC Bioimaging Facility) <br>

An environmentally friendly solution to one of the world’s most notorious chemical contamination problems may be a step closer to reality, reports a research team from Purdue University and the University of British Columbia.

The team has identified one of the key stumbling blocks that prevent microorganisms from decomposing PCBs (polychlorinated biphenyls), a persistent and potentially hazardous industrial chemical that has become nearly ubiquitous in the environment. While capitalizing on the discovery will take time, it could eventually show researchers how to teach microorganisms to break down PCBs into ecologically safe molecules, a process known as bioremediation.

“We have isolated one of the major hurdles to cleaning up PCBs naturally,” said Jeffrey T. Bolin, professor of biological sciences and a member of Purdue’s Markey Center for Structural Biology and Cancer Center. “This gives us a clear picture of one route to degrading PCBs in the environment.”

The research appears on the press Web site of Nature Structural Biology.

PCBs were manufactured and used widely in industry for decades, but the 1960s and 1970s brought increased awareness of their toxicity to animals and mass poisonings linked to PCB-contaminated food. PCBs are no longer manufactured in the United States, but their persistence makes them a worldwide problem because many suggested cleanup methods, such as incineration, are ineffective, sometimes even generating other toxic compounds such as dioxins.

“The globe’s entire surface is now contaminated with PCBs,” Bolin said. “They are in the soil you walk on and in Arctic ice. They accumulate in organisms as you go up the food chain, especially in aquatic environments, which means that creatures that eat fish – like humans – are particularly likely to absorb large quantities.”

Many harmful chemicals in the environment are broken down into benign substances naturally by microorganisms, but PCBs have persisted for decades because decomposers, such as bacteria and fungi, do not find them tasty – at least, not tasty enough.

“PCB molecules actually look very similar to many organic molecules that certain bacteria eat,” Bolin said. “But there are enough little differences that bacteria can’t quite digest them. It’s frustrating, because if bacteria could fully digest PCBs, it might solve a worldwide pollution problem. We asked ourselves: What could we do to improve bacterial digestion of PCBs?”

To answer the question, the group has adopted a twofold strategy: first, identify what aspect of PCB breakdown the bacteria are having trouble accomplishing, then breed bacteria to improve their talent at accomplishing it. Bolin said the group’s findings are a breakthrough for the first aspect.

“The process of digestion requires a long chain of chemical steps, and if the bacteria can’t accomplish one of those steps, the chain is broken and digestion can’t occur,” Bolin said. “What we have done is isolate one of the steps that causes problems for the bacteria, a clog in the biochemical pipeline if you will.”

Now that the group has perspective on this first aspect of the problem, they can focus on improving bacteria for battle against the PCB enemy. Bolin and his research partner, Lindsay Eltis, predict that microorganisms can learn to consume PCBs if properly bred.

“A species will fit itself to a new environment, given many generations to adapt,” said Eltis, associate professor of microbiology and biochemistry at the University of British Columbia. “In the case of bacteria, you can get new generations once every few minutes under proper laboratory conditions – just like breeding dogs, only much more rapidly. We hope to use certain species of bacteria with a slight taste for PCBs and improve this trait through breeding until it’s strong enough to make them consume PCBs as a food source.”

If the group succeeds, it could mean that PCBs’ days are numbered in the environment. But Eltis emphasizes that there remain difficulties ahead.

“We still have a great deal to do, and it will not be a simple matter to fit a species of bacteria to the task,” he said. “But the potential environmental rewards are inspiring. If we succeed, we could get the planet back to where it was before PCBs were ever manufactured.”

This research has been funded by the National Institutes of Health and Canada’s National Science and Research Council.

Writer: Chad Boutin, (765) 494-2081, cboutin@purdue.edu

Sources: Jeffrey Bolin, (765) 494-4922, jtb@purdue.edu

Lindsay Eltis, (604) 822-0042, leltis@interchange.ubc.ca

Purdue News Service: (765) 494-2096; purduenews@purdue.edu

Media Contact

More Information:

http://press.nature.com/All latest news from the category: Ecology, The Environment and Conservation

This complex theme deals primarily with interactions between organisms and the environmental factors that impact them, but to a greater extent between individual inanimate environmental factors.

innovations-report offers informative reports and articles on topics such as climate protection, landscape conservation, ecological systems, wildlife and nature parks and ecosystem efficiency and balance.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…