Simple, safe and reliable: Siemens develops a new sublance for LD converters

The system consists of a vertically mobile sublance, including a lance car and a special probe magazine. It combines a compact, inherently operationally safe drive design with a radar-based measuring system for fast, precise positioning of the lance, which can achieve measuring cycle times of less than 110 seconds. The system is simply and ruggedly constructed, resulting in higher reliability and lower maintenance costs.

Because they are physically close to the converters in the steel works, sublances are exposed to severe environmental conditions, such as high temperatures and heavy concentrations of dust in the ambient air. This makes maintaining and servicing lance systems correspondingly difficult and expensive.

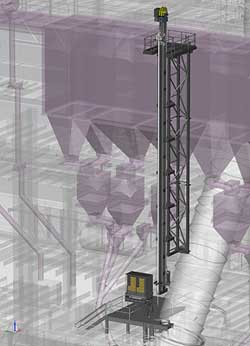

The new Simetal Sublance 2.0 from Siemens is designed for installation above the converter cooling stack. Measurements and samples are taken through a port in the stack. The drive system of the sublance is designed on the same principle as that of an elevator. Two redundant steel ropes fed over non-slip traction sheaves connect the vertically mobile lance car to a counterweight. This is slightly heavier than the lance traveling device, so the device can be returned to its starting position in the event of a power outage or drive malfunction. This greatly increases operational safety. As only a low net weight has to be lifted, the drive motor can also have smaller dimensions, and the lance car can be moved more quickly and precisely than with conventional drive solutions. This facilitates measuring cycle times of just 110 seconds.

The lance car is equipped with multiple, adjustable rollers that ensure smooth motion along the guiding rails. The sublance itself is attached to the lance car by a quick coupling device. The lance, together with the water supply, is automatically coupled by means of its own dead weight. Additional screws prevent accidental unhinging. The quick coupling enables the lance to be changed quickly and easily, as well as simply rotated through 180°. The lance can also be turned by hand to compensate for any thermal distortion. A centering device is mounted at the lower end of the guiding rail to position the tip of the lance precisely, even at a high operating speed. The lance is positioned by means of a measuring encoder on the drive and a non-contact radar system. No additional position encoders are required on the rails themselves. This increases both the reliability and the safety of the system. All measuring sensors are mounted on the drive platform for easy access.

Siemens has developed a new magazine solution for handling and holding the probes. The magazine has up to five storage boxes, each of which can hold 20 probes for long-term operation. Each box indicates the precise number of probes it contains, and sends a message to the control center when this falls below a settable limit. The boxes can be refilled by hand. A probe is rotated from the horizontal storage position into the vertical position by a special guiding rail. This turns the probe with the aid of its dead weight, and does not require any additional mechanical drives. Before mounting on the lance, the probe is fixated in a vertical position by a gripper, which also removes it after the measurement has been made.

A supplementary solution for automated calibration of the measuring system is currently under development. The Simetal Sublance 2.0 can also be combined with the Siemens LiquiRob robot system.

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of innovative and environmentally friendly products and solutions for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the Sector enhances its customers' productivity, efficiency, and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies. For more information, visit http://www.siemens.com/industry

The Metals Technologies Business Unit (Linz, Austria), part of the Siemens Industry Sector, is one of the world's leading suppliers of plant construction and engineering in the iron and steel industry as well as in the flat rolling segment of the aluminum industry. The Business Unit offers a comprehensive product and service portfolio for metallurgical plants and equipment as well as integrated automation and environmental solutions covering the entire lifecycle of plants. For more information, visit http://www.siemens.com/metals

Reference Number: IMT201203144

Contact

Mr. Rainer Schulze

Metals Technologies

Siemens AG

Turmstr. 44

4031 Linz

Austria

Tel: +49 (9131) 7-44544

rainer.schulze@siemens.com

Media Contact

More Information:

http://www.siemens.com/metalsAll latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…