Position detection in hydraulic cylinders

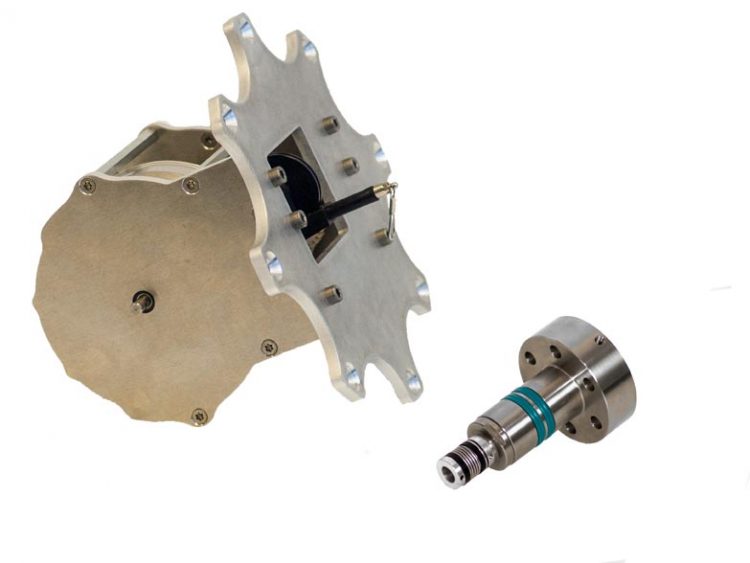

Integrated position detection with the patented Draw Wire Encoder SX200up

The patented SX200 is one of the few Draw Wire Encoders that can be integrated into hydraulic cylinders and can measure a stroke of up to 12m. No other measurement principle reaches this measuring range without removing the cylinder, with a simultaneous integration of the measuring system.

Due to the way the hydraulic cylinder is assembled, the entire measuring system is optimally protected. The SX200 is remarkably suited to application in confined spaces. The measuring cable is connected to the piston and is pulled from the sensor during the operation of the cylinder.

In the sensor itself, the measuring cable is coiled around a cable sheave, which rotates with each cylinder stroke, thereby turning the linear movement into a rotation. Through a sealed shaft (pressure implementation) the rotary movements are directed outwards into an unpressurized area and recorded by a sensor element (e.g. a digital absolute rotary encoder).

Through the evaluation of sensor signals, not only is the position of the piston rod regulated, but the specific cylinder positions are also recorded and the synchronic movement of multiple cylinders is ensured. The highly dynamic sensors also allow for rapid cylinder movements during this process.

The compact casing, as well as adaptation to customer needs, qualify this sensor technology for multiple areas of application. Thanks to its robust construction and high quality, the sensor can be employed in harsh industrial environments.

Typical applications for the Draw Wire Encoder SX200 are: Hydraulic gates on dams; monitoring of simultaneously running cylinders; regulation and monitoring of traverse speed.

Technical information concerning the SX200 is available here:

www.waycon.biz/draw-wire-sensor-SX200.pdf

Further information is available at:

http://www.waycon.biz/products/draw-wire-sensors/

Background information

WayConPositionsmesstechnik GmbH has been developing and manufacturing precision sensors for position and distance measurement since 1999. As an innovative company with headquarters in Taufkirchen near Munich and a branch in Brühl near Cologne, we sell our products all over the world. Our goal is to provide our customers with the best possible measurement technique solution: from high-quality sensors from the standard range to customer-specific solutions, from prototype to series production – for the most varied applications in industry and research. The products made in Taufkirchen are subject to rigorous quality standards and every single one is delivered to our customers with a calibration certificate.

Contact

WayCon Positionsmesstechnik GmbH

Marcus Venghaus

Mehlbeerenstraße 4

82024 Taufkirchen

E-Mail: presse@waycon.de

Internet: www.waycon.de/home/

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…