New services for online condition monitoring of industrial plants

Siemens now offers "Asset Analytics Services", a new service for online condition monitoring of machines, production lines, and even entire industrial plants.

As part of the service, Siemens experts assist companies in recording and analyzing operating and condition-based data. The aim is to provide a clear picture on the state of critical machinery and plant and therefore to optimize their availability.

Siemens is offering the new condition monitoring service based on a scalable cloud infrastructure, making it suitable for companies of different sizes and from different industries and for a wide range of industrial applications.

In Asset Analytics Services, large volumes of physical data, such as vibration, temperature, or pressure levels, and process data from the control system are recorded in real time, before being preprocessed and transmitted to a Siemens Operation Center for analysis. Conformity with the Siemens security standard CERT and with ISO 27001 ensures the greatest possible data security. In the Siemens Operation Center, the data are analyzed and the results are sent to the customer via a web portal or as a report.

This also includes automatic alarming when critical limits are reached. The continuous acquisition and automated analysis of operating and condition-based data mean that any patterns, such as data profiles of damage incidents, can be detected at an early stage. System malfunctions can thus be remedied in good time and production outages avoided, helping companies to optimize their maintenance activities.

The Asset Analytics Services are available for various applications, for example, for condition monitoring of machine tools (“Machine Tool Analytics Services”). The focus here is on critical components, such as linear axes, main spindles, tool magazines, chip conveyors, or the automation technology with pneumatics and fluid systems.

For rotary industrial applications, such as pumps, compressors, or mills, Siemens provides “Asset Analytics Services for Rotating Equipment.” Asset Analytics Services make it possible to monitor whole production lines, for example, press lines in the automotive industry. Measured values from ongoing operations and data from the plant control system can be analyzed, for example, oil pressure, air consumption, or press angle.

The company's portfolio also includes services for monitoring the industrial IT infrastructure. For example, the “Industrial Network Analytics Services” covers the diagnostics and continuous condition monitoring of plant networks. The individual services can be combined and expanded to include the analysis and optimization of entire industrial plants.

Based on the new offerings, Siemens is expanding its range of “Data-Driven Services,” based on the acquisition and evaluation of production data.

For further information on Asset Analytics Services, please see

www.siemens.com/data-driven-services

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of innovative and environmentally friendly automation and drive technology, industrial software and technology-based services. The Sector's comprehensive portfolio covers the entire industrial value chain, from product design, engineering and production to services. Siemens enhances its customers' productivity, efficiency, and flexibility in a wide variety of different industries. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies. For more information, visit http://www.siemens.com/industry

Reference Number: I2014032505e

Contact

Mr. David Petry

Customer Services Division

Siemens AG

Schuhstr. 60

91052 Erlangen

Germany

Tel: +49 (9131) 7-26616

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…

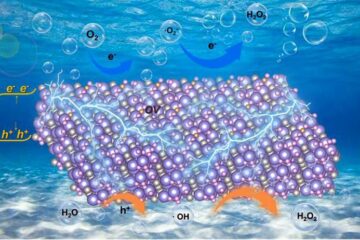

Oxygen vacancies mediated ultrathin Bi4O5Br2 nanosheets

… as efficient piezocatalyst for synthesis of H2O2 from pure water. As an important chemical raw material, hydrogen peroxide (H2O2) is widely applied in various aspects of industry and life….