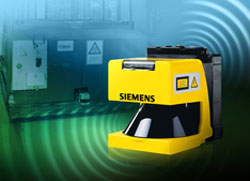

New laser scanners safeguard small protection zones and transfer carriages

Typical applications for the Simatic FS660 SR include low-speed driverless transport systems of up to two meters with a short braking path.

In fixed installations, the device, which is equipped with horizontal and vertical protection, is particularly suitable for access protection at low openings, e.g. at robot cells or to protect the area around cutters and presses. The new scanner has a 190 degree field of operation, four programmable and switchable protection zones and one invisible infrared laser (Laser Protection Class 1).

In addition to the standard safety functions for personnel protection, the new Simatic FS670 laser scanner for motion monitoring reliably calculates positioning distances and speeds. It monitors as many as six different speeds and, if necessary, automatically corrects the selected protection zone.

This eliminates the need for additional incremental encoders for “speed-dependent protection zone monitoring”. This function is performed jointly by laser scanners and standard controllers. The new unit has eight programmable and switchable protection zones with ranges of between 2.15 and 4 meters (ranges of up to 6 meters will be available soon). The resolution can be adjusted from 30 to 150 mm. The protection zones are calculated automatically by the LS4Soft software.

Both scanners are certified according to Type 3 as per IEC/EN 61496-1 and -3, SIL 2 as per IEC 61508 and PL d as per EN ISO 13849. They are parameterized using the LS4Soft software.

Media Contact

More Information:

http://www.siemens.com/simatic-sensors/fsAll latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

Machine learning algorithm reveals long-theorized glass phase in crystal

Scientists have found evidence of an elusive, glassy phase of matter that emerges when a crystal’s perfect internal pattern is disrupted. X-ray technology and machine learning converge to shed light…

Mapping plant functional diversity from space

HKU ecologists revolutionize ecosystem monitoring with novel field-satellite integration. An international team of researchers, led by Professor Jin WU from the School of Biological Sciences at The University of Hong…

Inverters with constant full load capability

…enable an increase in the performance of electric drives. Overheating components significantly limit the performance of drivetrains in electric vehicles. Inverters in particular are subject to a high thermal load,…