New gear unit series for high torques

With its high torque range, the new gear units are especially suited for applications in the steel and cement industries, conveyor systems, and sugar production.

At this year’s Hannover Messe, Siemens is unveiling a new gear unit series for high torques of up to 1.4 million newton-meters (Nm). With this new addition, Siemens now offers gear unit series covering a torque range from 3,000 Nm to 1,400,000 Nm.

The gear units are available as spur gear and bevel spur gear versions with gear ratios from 1 to 450. The gear unit series features a modular design and is built entirely of standard components. This means that low-cost gear unit series are now also available for applications that were forced to use custom-built components due to high torque requirements.

The heavy industrial gears in the Flender series are offered as two to four-stage spur gear and bevel spur gear units, and for horizontal or vertical mounting positions. The high degree of standardization means that both gear and bevel spur gear versions can be installed with the same components and standard enclosures. Both versions also offer the same output shaft solutions for different output concepts.

The progressive ratio of sizes allows fine gradation in the high torque range. Special requirements are implemented by the use of standard components or custom solutions, but they are always based on the modular system. The heavy industrial gears may be used universally in all applications that require high torque, as in the steel and cement industries, conveying systems, and sugar production.

Media Contact

More Information:

http://www.siemens.com/gearsAll latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

A chip unique in the world

A team from UPV and iPRONICS has manufactured the first universal, programmable and multifunctional photonic chip on the market. A team from the Photonics Research Laboratory (PRL)-iTEAM of the Universitat…

Advance in light-based computing

…shows capabilities for future smart cameras. UCLA-developed experimental device demonstrates ability to reduce glare in images. Researchers developing the next generation of computing technology aim to bring some light to…

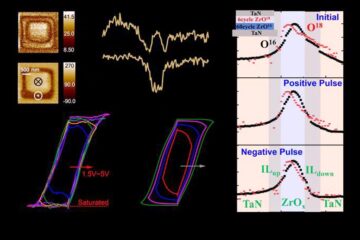

Evidence for reversible oxygen ion movement during electrical pulsing

…enabler of the emerging ferroelectricity in binary oxides. In a recent study published in Materials Futures, researchers have uncovered a pivotal mechanism driving the emergence of ferroelectricity in binary oxides….