Only 330 working days left until changeover to high-efficiency motors

From June 16, 2011, in accordance with EU Directive 2005/32/EC, only high-efficiency 2 to 6-pole three-phase asynchronous motors will be permitted on the European market.

They must at least comply with efficiency class IE2 (IE=International Efficiency) which corresponds to the currently highest European efficiency class EFF1. The efficiency of high-efficiency motors can be up to seven percent higher than that of standard motors, which means that less current is drawn for the same output. Drive systems consume more than two-thirds of industrial energy, so this will reduce carbon-dioxide emissions.

At the same time the operating costs are reduced for the user, such that the additional costs for the higher efficiency are paid back in a short time. The operator can therefore save around 100 Euros in energy costs by implementing a 4-pole 2.2 kW motor of efficiency class IE2 instead of an IE1 motor. In continuous duty, at a rate of eight cents per kilowatt-hour, the additional costs are paid back in a year. Replacement is easy due to the identical housing dimensions of IE1 and IE2 motors.

The Siemens Drive Technologies Division supplies all the motor series that are affected by the new legislation and has short delivery times for standard catalog motors. The user is also supported with documentation, such as data sheets, and online tools such as the DT Configurator or the Sinasave energy-saving tool.

The Siemens Industry Sector (Erlangen, Germany) is the worldwide leading supplier of environmentally friendly production, transportation, building and lighting technologies. With integrated automation technologies and comprehensive industry-specific solutions, Siemens increases the productivity, efficiency and flexibility of its customers in the fields of industry and infrastructure. The Sector consists of six divisions: Building Technologies, Drive Technologies, Industry Automation, Industry Solutions, Mobility and Osram. With around 207,000 employees worldwide (September 30), Siemens Industry achieved in fiscal year 2009 total sales of approximately €35 billion. www.siemens.com/industry

The Siemens Drive Technologies Division (Nuremberg, Germany) is the world's leading supplier of products and services for production machinery and machine tools. This includes standard products but also encompasses industry-specific control and drive solutions. Integrated technologies along the entire drive train with electrical and mechanical components offer highest potential to reduce energy consumption in industrial plants. The services provided by the Division include mechatronics support in addition to online services for web-based fault management and preventive maintenance. With around 36,000 employees worldwide (September 30), Siemens Drive Technologies achieved total sales of €7.5 billion in fiscal year 2009. www.siemens.com/drivetechnologies

Reference Number: IDT2010032318e

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

A flexible and efficient DC power converter for sustainable-energy microgrids

A new DC-DC power converter is superior to previous designs and paves the way for more efficient, reliable and sustainable energy storage and conversion solutions. The Kobe University development can…

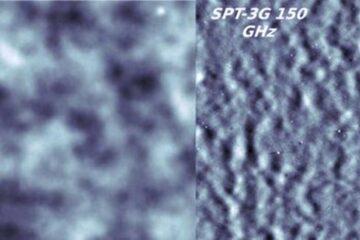

Technical Trials for Easing the (Cosmological) Tension

A new study sorts through models attempting to solve one of the major challenges of contemporary cosmic science, the measurement of its expansion. Thanks to the dizzying growth of cosmic…

Peptides on Interstellar Ice

A research team led by Dr Serge Krasnokutski from the Astrophysics Laboratory at the Max Planck Institute for Astronomy at the University of Jena had already demonstrated that simple peptides…