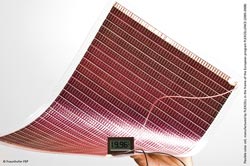

Weathering-resistant and long-term stable solar film for building-integrated photovoltaics

Encapsulation films for flexible solar cells will be adapted to environmental conditions such as UV-radiation in the »flex25« project.<br>

Such solar cells would allow those parts of a building that have been unused up to now to be exploited for the generation of electrical energy – including industrial flat roofs, facades or large window areas.

Buildings have so far been used only by a small percentage to produce energy. But facades, window panes, sunshades or flat roofs offer huge open spaces in which photovoltaic modules could be integrated.

It is expected that up to 50 percent of the energy demand could be satisfied with building-integrated photovoltaics (BIPV) in the long term. Thin-film photovoltaics open up whole new ways of integrating photovoltaic elements in the building envelope on account of their flexibility, low weight and the possibility of adjusting different levels of transparency and colors.

But flexible solar cells to date often lack weathering-resistance and a satisfactory service lifetime. The active layers within a thin-film solar module in particular are very sensitive to water-vapor and oxygen and have to be given the best possible protection against ambient conditions.

The Fraunhofer Institutes for Electron Beam and Plasma Technology FEP, for Silicate Research ISC and for Process Engineering and Packaging IVV, have already developed layer systems and production processes in multi-annual research projects which allow flexible electronic products such as organic light-emitting diodes (OLEDs) or displays to be very effectively protected against water-vapor and oxygen. The technology developed by the scientists currently achieves one of the lowest water-vapor permeability values for roll-to-roll produced systems in the world.

In order to make the proven layer system suitable for outdoor applications, such as its use in flexible solar modules, the scientists are aiming to improve the UV- and weathering-resistance of the encapsulating film within the frame of the »flex25« project (reference number: 03V0224, duration: 3 years) which is being supported within the scope of the BMBF-grant »Validation of the innovative potential of scientific research – VIP«. The technology will be transferred to a weathering- and UV- resistant substrate and the resistance of the layer materials themselves to environmental impacts such as UV-radiation will be improved. The group will hereby exploit its experience in the field of photovoltaics and front side encapsulation. The ultimate aim of this project is the roll-to-roll production of a lightweight, long-term stable front encapsulation of flexible thin-film solar cells with a service lifetime of 25 years.

Currently an encapsulation film that is suitable for outdoor applications is not available anywhere in the world. However, such a film would be a key enabling technology for building-integrated photovoltaics. If the front glass of a typical solar module could be replaced by a polymer film, for example, its weight might be reduced by up to 40 percent and roofs or building parts with limited bearing load of the construction such as industrial flat roofs could be used for photovoltaics.

Press contact:

Annett Arnold

Fraunhofer-Institut für Elektronenstrahl- und Plasmatechnik FEP | Phone +49 351 2586 452 | Annett.Arnold@fep.fraunhofer.de

Winterbergstraße 28 | 01277 Dresden | Gemany | www.fep.fraunhofer.de

Media Contact

More Information:

http://www.fep.fraunhofer.deAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Machine learning algorithm reveals long-theorized glass phase in crystal

Scientists have found evidence of an elusive, glassy phase of matter that emerges when a crystal’s perfect internal pattern is disrupted. X-ray technology and machine learning converge to shed light…

Mapping plant functional diversity from space

HKU ecologists revolutionize ecosystem monitoring with novel field-satellite integration. An international team of researchers, led by Professor Jin WU from the School of Biological Sciences at The University of Hong…

Inverters with constant full load capability

…enable an increase in the performance of electric drives. Overheating components significantly limit the performance of drivetrains in electric vehicles. Inverters in particular are subject to a high thermal load,…