USC scientists create new battery that's cheap, clean, rechargeable… and organic

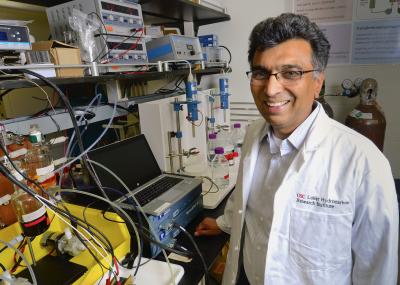

USC professor Sri Narayan's research focuses on the fundamental and applied aspects of electrochemical energy conversion and storage to reduce the carbon footprint of energy use and by providing energy alternatives to fossil fuel. Credit: USC Photo / Gus Ruelas

The new battery – which uses no metals or toxic materials – is intended for use in power plants, where it can make the energy grid more resilient and efficient by creating a large-scale means to store energy for use as needed.

“The batteries last for about 5,000 recharge cycles, giving them an estimated 15-year lifespan,” said Sri Narayan, professor of chemistry at the USC Dornsife College of Letters, Arts and Sciences and corresponding author of a paper describing the new batteries that was published online by the Journal of the Electrochemical Society on June 20. “Lithium ion batteries degrade after around 1,000 cycles, and cost 10 times more to manufacture.”

Narayan collaborated with Surya Prakash, Prakash, professor of chemistry and director of the USC Loker Hydrocarbon Research Institute, as well as USC's Bo Yang, Lena Hoober-Burkhardt, and Fang Wang.

“Such organic flow batteries will be game-changers for grid electrical energy storage in terms of simplicity, cost, reliability and sustainability,” said Prakash.

The batteries could pave the way for renewable energy sources to make up a greater share of the nation's energy generation. Solar panels can only generate power when the sun's shining, and wind turbines can only generate power when the wind blows. That inherent unreliability makes it difficult for power companies to rely on them to meet customer demand.

With batteries to store surplus energy and then dole it out as needed, that sporadic unreliability could cease to be such an issue.

“'Mega-scale' energy storage is a critical problem in the future of the renewable energy, requiring inexpensive and eco-friendly solutions,” Narayan said.

The new battery is based on a redox flow design – similar in design to a fuel cell, with two tanks of electroactive materials dissolved in water. The solutions are pumped into a cell containing a membrane between the two fluids with electrodes on either side, releasing energy.

The design has the advantage of decoupling power from energy. The tanks of electroactive materials can be made as large as needed – increasing total amount of energy the system can store – or the central cell can be tweaked to release that energy faster or slower, altering the amount of power (energy released over time) that the system can generate.

The team's breakthrough centered around the electroactive materials. While previous battery designs have used metals or toxic chemicals, Narayan and Prakash wanted to find an organic compound that could be dissolved in water. Such a system would create a minimal impact on the environment, and would likely be cheap, they figured.

Through a combination of molecule design and trial-and-error, they found that certain naturally occurring quinones – oxidized organic compounds – fit the bill. Quinones are found in plants, fungi, bacteria, and some animals, and are involved in photosynthesis and cellular respiration.

“These are the types of molecules that nature uses for energy transfer,” Narayan said.

Currently, the quinones needed for the batteries are manufactured from naturally occurring hydrocarbons. In the future, the potential exists to derive them from carbon dioxide, Narayan said.

The team has filed several patents in regards to design of the battery, and next plans to build a larger scale version.

This research was funded by the ARPA-E Open-FOA program (DE-AR0000337), the University of Southern California, and the Loker Hydrocarbon Research Institute.

Media Contact

More Information:

http://www.usc.eduAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…