Uprated Siemens D3 wind turbine implements sum of design and operational experiences

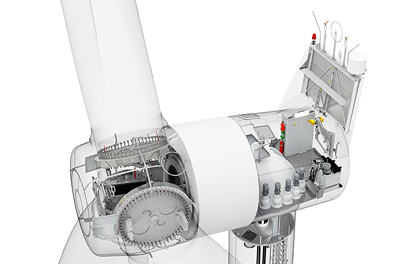

Proven platform, refined technology: The uprated Siemens D3 wind turbines combine experience and innovation.

Siemens Energy has uprated its D3 onshore platform wind turbines. The new SWT-3.2-101, SWT-3.2-108 and SWT-3.2-113 machines feature improved performance from 3.0 to 3.2 megawatts (MW) and implement the sum of design and operational experiences. The uprated products will enter serial production by the end of 2014. They will be available with 101 and 108 meter rotors for IEC class IA sites, and a 113 meter rotor for IEC class IIA sites. The 3 MW version will remain available for project sites with lower wind speeds.

Simplicity and efficiency were the key words when Siemens developed its first commercial direct drive turbine in 2009. Following five years of experience and a large number of D3 wind turbines installed worldwide, the fundamental approach remains the same, but the technology continues to be refined. The uprated Siemens D3 wind turbines represent a classical wind turbine evolution, combining the reliability of a proven and tested concept with cutting edge technology development. Improvements in the turbine control system and increased efficiency through the use of stronger magnets are the key factors that allowed Siemens to get more power out of the D3 drivetrain.

The uprating underlines the structural reserves already found in the construction of Siemens' gearless wind turbines. “One important goal of our development work is to utilize innovation to further tap the technical potential of our products,” says Henrik Stiesdal, CTO of Siemens Wind Power. “Rotors, structures and performance have been tested intensively to simulate more than 20 years of lifetime stress. This resulted in a new product generation which offers the reliability of the predecessor while delivering up to 4 percent more energy yield.”

Wind power and the associated service activities are part of Siemens' Environmental Portfolio. Around 43 percent of the company's revenues are generated by green products and solutions. That makes Siemens one of the world's leading providers of eco-friendly technology.

More information about the trade fair appearance is available at www.siemens.com/energy/ewea2014

The Siemens Energy Sector is the world's leading supplier of a complete spectrum of products, services and solutions for power generation in thermal power plants and using renewables, power transmission in grids and for the extraction, processing and transport of oil and gas. In fiscal year 2013 (ended September 30) the Energy Sector had revenues of EUR 26.6 billion and received new orders totaling approximately EUR 28.8 billion, and posted a profit of approximately EUR 2.0 billion. On September 30, 2013, Siemens' Energy Sector had a workforce of about 83,500. Further information is available at: http://www.siemens.com/energy

Reference Number: EWP201403030e

Contact

Mr. Bernd Eilitz

Energy Sector

Siemens AG

Lindenplatz 2

20099 Hamburg

Germany

Tel: +49 (40) 2889-8842

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…