Telltale heat

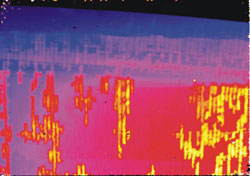

This is a thermographic image of air inclusions (light-colored) in a rotor blade. Credit: Fraunhofer WKI

A full, deep sound tells him that the laminate is homogeneous, while a more flat, hollow tone indicates irregularities in the material.

Delaminated and hollow sections of a certain size near the surface can also be detected by running an expert hand over the surface material. But even an experienced inspector cannot find all hidden faults in this way.

Rotor blades consist mainly of glass fibers which are processed to form mats or meshes. In order to make a 60-meter rotor blade, hundreds of these mats have to be laid flat inside a mold and impregnated with special resins in a vacuum.

Even minor irregularities can cause air bubbles or other faults to form, and these often lead to mechanical stresses in the material when the blade is subjected to everyday loads. As a consequence, the laminate can rip and cause the rotor blades to fail prematurely.

Researchers at the Fraunhofer Wilhelm-Klauditz-Institut WKI in Braunschweig are able to make such faults visible. “Infrared thermography is well suited to this task, as it is fast, relatively cheap and doesn't cause any damage,” explains WKI project manager Dr. Hiltrud Brocke. “The surface is briefly heated with an infrared radiator. A special camera shows how the heat front spreads inside the material. If the front hits on any air inclusions or delaminated areas, it accumulates because heat spreads less in air than in solid laminate.”

In this way, the researchers can peer several centimeters into the material. “Because the equipment – the infrared radiator, a camera and a computer – is mobile, we can carry out measurements during production, at the end of the transport route, and also on fully assembled wind energy plants,” says Brocke. The researchers will be demonstrating their technology on a rotor blade section incorporating several typical faults at the Hannover-Messe from April 20 to 24 (Hall 27, Stand G20).

Media Contact

More Information:

http://www.wki.fraunhofer.deAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…