Simulations to enable novel lithographic patterning techniques

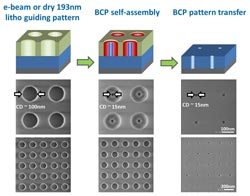

Shrink and rectification of contact holes using a DSA process with block copolymers (BCP). Upper row: schematic process flow, scanning electron microscope (SEM) images of resulting patterns.<br>R. Tiron (LETI)<br>

Advanced simulation models and a computational framework for lithography-integrated directed self-assembly (DSA) of block copolymers will be developed within the European project CoLiSA.MMP. These software tools will aid the research and development of new materials, designs and process flows.

By enhancing existing and future lithographic patterning techniques, DSA of block copolymers can help to further extend the impressive development in semiconductor technologies. Cost-efficient technologies for the miniaturization of patterns in semiconductor devices are key to the development of more powerful computers, mobile devices and many other types of consumer and industrial electronics. CoLiSA.MMP combines European expertise in soft matter physics, block copolymer chemistry, lithographic process and computational lithography.

For many technology generations, the miniaturization of semiconductor devices was enabled by evolutionary advancements in optical projection lithography. In the past, this was mainly achieved by the reduction of the wavelength or an increase of the numerical aperture (NA). Today with size requirements close to the physical limits, highly involved methods such as optical resolution enhancement techniques, source and mask optimization (SMO), double patterning and lithography-friendly design are required. Only with the help of these, can the downscaling pace of Moore’s law be maintained, allowing for technology nodes as small as 22 nanometers.

The extension of optical lithography to even smaller dimensions will lead to a drastic increase in costs. Extreme ultraviolet (EUV) lithography, at a wavelength of 13.5 nanometers for example, promises a revival of wavelength-driven scaling. Because of major unresolved obstacles associated with the source power and stability and the mask infrastructure, the introduction of EUV has been repeatedly postponed. Directed self-assembly (DSA) of block copolymers offers an alternative approach to scaling. It employs nanophase separation between covalently bound chemically different monomers. In contrast to traditional, increasingly difficult and expensive optics-driven top-down technologies, DSA uses a cost-efficient material-driven bottom-up technique, permitting structures of 10 nanometers and below.

Two challenges still impede an industry-grade application of DSA: 1st, the host substrate strongly impacts DSA. The resulting pattern formation must be understood and modeled exactly in order to optimize its efficiency and to circumvent defects. 2nd, the specific properties of DSA must be considered early during the design stage. Within CoLiSA.MMP novel material and process models and a computational lithography framework for DSA will be developed. The combination of advanced, tailored atomistic and coarse-grained models and a series of complementary experiments, serves as the foundation for the development of highly efficient reduced models that seamlessly integrate into the lithographic process simulation. The new modeling facilities will be used to establish advanced design flows, which account for both the lithographic generation of guiding patterns and the patterns resulting from DSA. By posing the design problem as an inverse one, lithographically manufacturable guiding patterns and process conditions for given target structures can be precisely predicted and at a very early stage. Computational lithography will be also used to investigate the root causes of DSA-specific defects and to propose strategies to avert or mitigate them.

To achieve these ambitious goals, a consortium of European research institutes, universities and a commercial material supplier has been formed, which covers a wide range of expertise in atomistic and coarse-grained modeling of polymers, design and synthesis of block copolymers, lithographic process implementation, computational lithography, and industrial exploi-tation strategies.

On November 19 and 20, 2013, Fraunhofer IISB in Erlangen, Germany, hosted the kick-off meeting for the 3-year project, which has a total budget of 4.91 million Euros.

CoLiSA.MMP is funded by the European Union in the 7th Framework Programme, under the ICT project number 619793.

Contact

Dr. Andreas Erdmann

Fraunhofer IISB

Schottkystrasse 10, 91058 Erlangen, Germany

Tel. +49-9131-761-258

Fax +49-9131-761-212

info@colisa.eu

Fraunhofer IISB

The Fraunhofer Institute for Integrated Systems and Device Technology IISB is one of 66 institutes in the Fraunhofer-Gesellschaft. Here, applied research and development is carried out in micro- and nano-electronics, power electronics and mechatronics. With a staff of 180 employees, the institute is committed to contract research for industry and public authorities.

Fraunhofer IISB is internationally recognized for the development of technology, equipment, and materials for nano-electronics and its work on power electronic systems for energy efficiency, hybrid and electric cars.

In addition to its headquarters in Erlangen, the IISB maintains two branch laboratories in Nuremberg and Freiberg.

The institute closely cooperates with the Chair of Electron Devices of the Friedrich-Alexander-Universität Erlangen-Nürnberg.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Machine learning algorithm reveals long-theorized glass phase in crystal

Scientists have found evidence of an elusive, glassy phase of matter that emerges when a crystal’s perfect internal pattern is disrupted. X-ray technology and machine learning converge to shed light…

Mapping plant functional diversity from space

HKU ecologists revolutionize ecosystem monitoring with novel field-satellite integration. An international team of researchers, led by Professor Jin WU from the School of Biological Sciences at The University of Hong…

Inverters with constant full load capability

…enable an increase in the performance of electric drives. Overheating components significantly limit the performance of drivetrains in electric vehicles. Inverters in particular are subject to a high thermal load,…