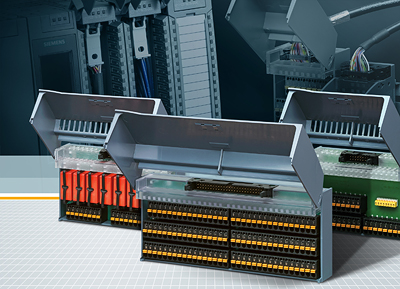

Simple wiring in the control cabinet

Siemens has broadened its Simatic Top Connect portfolio with a range of new modules and system components for fast and safe wiring of Simatic S7-1500 and Simatic ET 200MP. With system cabling, users can save up to 80 percent time compared to conventional single wiring using terminal blocks.

In addition to connection modules for eight channels (inputs or outputs), Siemens also offers, for the first time, compact versions for 32 channels that are available for connecting sensors and actuators via one or three wires.

Thereby only one cable needs to be connected between the connection module and the S7-1500 controller instead of four for the individual 8-channel modules. In addition, the new 32-channel connection module requires less space on the mounting rail than four modules with eight inputs and outputs each. The new connection modules feature the compact design of the Simatic S7-1500, allowing space-saving installation in the control cabinet. With system cabling, users can save up to 80 percent time compared to conventional single wiring using terminal blocks.

The connection modules with eight channels are available in different versions, with disconnect terminals for manually cutting off specific plant sections, for example, or with relays and optocouplers for adapting the potential with which signals with AC voltages of 110 or 230 volts can also be connected to the controller. The 8-channel connection modules are fully compatible with the field-proven front connector modules for Simatic S7-300 and ET 200 M.

The appropriate system cabling can be selected in accordance with the respective input or output modules simply and quickly in the TIA Selection Tool.

For further information, please see www.siemens.com/simatic-tc

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of innovative and environmentally friendly automation and drive technology, industrial software and technology-based services. The Sector's comprehensive portfolio covers the entire industrial value chain, from product design, engineering and production to services. Siemens enhances its customers’ productivity, efficiency, and flexibility in a wide variety of different industries. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies. For more information, visit http://www.siemens.com/industry

Reference Number: I2014022406e

Links

Contact

Mr. Peter Jefimiec

Industry Automation Division

Siemens AG

Gleiwitzerstr. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7975

Media Contact

More Information:

http://www.siemens.comAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…