Siemens develops new electric arc furnace for direct reduced iron melting

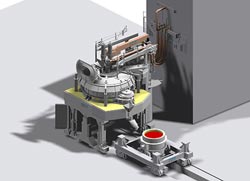

Simetal EAF FAST DRI from Siemens. The new arc furnace was specially designed for the use of direct reduced iron.<br>

Siemens VAI Metals Technologies offers steelworks operators an electric arc furnace that has been specially developed for the use of DRI (direct reduced iron). The Simetal EAF FAST DRI is designed for a continuous melting process as electrical energy input and DRI are supplied during tapping. This shortens tap-to-tap times and reduces specific energy consumption. An overall productivity increase of around 15 percent can be achieved with a 150-ton furnace. The arc furnace has a modular structure, which also makes it possible to retrofit existing, conventional furnaces. With this new furnace concept Siemens underlines its technological leadership in electric steelmaking.

The Simetal EAF FAST DRI electric arc furnace has a tiltable lower vessel with an extensive liquid heel. The resulting continuous flat-bath operation allows electrical energy input and DRI feeding during tapping. Thanks to the patented furnace advanced slag-free tapping system (FAST), charging, tapping and taphole refilling are possible under power-on conditions. Compared with conventional arc furnaces, tap-to-tap times can be reduced by up to 15 percent. Energy consumption is cut by 20 kilowatt-hours per ton and electrode consumption falls by ten percent. The continuous supply of electrical energy during flat-bath operation not only improves productivity, but also avoids line harmonic distortions such as flicker.

The continuous operation of the furnace offers a number of other benefits. Coal and oxygen injection as well as foaming slag control can be implemented even more precisely. Slag- free tapping results in an enhanced alloys yield and better steel desulfurization. Installation of additional burners thus becomes superfluous. Thermal stress on the refractory and structure materials also remains constant, prolonging their useful lives.

The Simetal EAF FAST DRI is designed so that, in combination with the Hot Transport System (HTS) from Siemens, it can also be fed with hot DRI at temperatures of around 600 °C. Thanks to the modular design of the new electric arc furnace, existing furnace installations can also be retrofitted with FAST DRI technology.

Further information about solutions for steel works, rolling mills and processing lines is available at http://www.siemens.com/metals

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of innovative and environmentally friendly products and solutions for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the Sector enhances its customers' productivity, efficiency, and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies. For more information, visit http://www.siemens.com/industry

The Metals Technologies Business Unit (Linz, Austria), part of the Siemens Industry Sector, is one of the world's leading suppliers of plant construction and engineering in the iron and steel industry as well as in the flat rolling segment of the aluminum industry. The Business Unit offers a comprehensive product and service portfolio for metallurgical plants and equipment as well as integrated automation and environmental solutions covering the entire lifecycle of plants. For more information, visit http://www.siemens.com/metals

Reference Number: IMT201201071e

Contact

Mr. Rainer Schulze

Metals Technologies

Siemens AG

Turmstr. 44

4031 Linz

Austria

Tel: +49 (9131) 7-44544

rainer.schulze@siemens.com

Media Contact

More Information:

http://www.siemens.comAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…