Purdue engineers create safer, more efficient nuclear fuel, model its performance

Purdue University nuclear engineers have developed an advanced nuclear fuel that could save millions of dollars annually by lasting longer and burning more efficiently than conventional fuels, and researchers also have created a mathematical model to further develop the technology.

New findings regarding the research will be detailed in a peer-reviewed paper to be presented on Oct. 6 during the 11th International Topical Meeting on Nuclear Reactor Thermal Hydraulics in Avignon, France. The paper was written by Shripad Revankar, an associate professor of nuclear engineering; graduate student Ryan Latta, now an engineer at Brookhaven National Laboratory; and Alvin A. Solomon, a professor of nuclear engineering.

The research is funded by the U.S. Department of Energy and focuses on developing nuclear fuels that are better at conducting heat than conventional fuels. Current nuclear fuel is made of a material called uranium dioxide with a small percentage of a uranium isotope, called uranium-235, which is essential to induce the nuclear fission reactions inside current reactors.

“Although today’s oxide fuels are very stable and safe, a major problem is that they do not conduct heat well, limiting the power and causing fuel pellets to crack and degrade prematurely, necessitating replacement before the fuel has been entirely used,” Solomon said.

Purdue researchers, led by Solomon, have developed a process to mix the uranium oxide with a material called beryllium oxide. Pellets of uranium oxide are processed to be interlaced with beryllium oxide, or BeO, which conducts heat far more readily than the uranium dioxide.

This “skeleton” of beryllium oxide enables the nuclear fuel to conduct heat at least 50 percent better than conventional fuels.

“The beryllium oxide is like a heat pipe that sucks the heat out and helps to more efficiently cool the fuel pellet,” Solomon said.

A mathematical model developed by Revankar and Latta has been shown to accurately predict the performance of the experimental fuel and will be used in future work to further develop the fuel, Revankar said.

Pellets of nuclear fuel are contained within the fuel rods of nuclear fission reactors. The pellets are surrounded by a metal tube, or “cladding,” which prevents the escape of radioactive material.

Because uranium oxide does not conduct heat well, during a reactor’s operation there is a large temperature difference between the center of the pellets and their surface, causing the center of the fuel pellets to become very hot. The heat must be constantly removed by a reactor cooling system because overheating could cause the fuel rods to melt, which could lead to a catastrophic nuclear accident and release of radiation – the proverbial “meltdown.”

“If you add this high-conductivity phase beryllium oxide, the thermal conductivity is increased by about 50 percent, so the difference in temperature from the center to the surface of these pellets turns out to be remarkably lower,” Solomon said.

Revankar said the experimental fuel promises to be safer than conventional fuels, while lasting longer and potentially saving millions of dollars annually.

“We can actually enhance the performance of the fuel, especially during an accident, because this fuel heats up less than current fuel, which decreases the possibility of a catastrophic accident due to melting,” Revankar said. “The experimental fuel also would not have to be replaced as often as the current fuel pellets.

“Currently, the nuclear fuel has to be replaced every three years or so because of the temperature-related degradation of the fuel, as well as consumption of the U-235. If the fuel can be left longer, there is more power produced and less waste generated. If you can operate at a lower temperature, you can use the fuel pellets for a longer time, burning up more of the fuel, which is very important from an economic point of view. Lower temperatures also means safer, more flexible reactor operation.”

Solomon said a 50 percent increase in thermal conductivity represents a significant increase in performance for the 103 commercial nuclear reactors currently operating in the United States.

“Just a 5 to 10 percent increase would be pretty significant, so a 50 percent increase would be quite an improvement,” Solomon said.

The next step in the research is to test the new fuel inside a nuclear reactor to make sure it stands up to the extreme conditions inside reactors over its entire lifetime.

“We know it holds up well to very high temperatures, and now we are at the point where we want to irradiate this material and see what it does,” Solomon said.

The researchers also had created fuel pellets containing fingers of another high thermal conductivity material called silicon carbide, but the silicon carbide reacted with the uranium oxide at elevated temperatures. New fuel designs made of compatible uranium compounds are presently being studied. The research paper being discussed in October concentrates on the model’s accuracy in predicting the results of experiments with silicon carbide and beryllium oxide, Revankar said.

Writer: Emil Venere, (765) 494-4709, venere@purdue.edu

Sources: Alvin A. Solomon, (765) 494-5753, solomon@ecn.purdue.edu

Shripad T. Revankar, (765) 496-1782, shripad@ecn.purdue.edu

Purdue News Service: (765) 494-2096; purduenews@purdue.edu

Media Contact

More Information:

http://www.purdue.eduAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A cause of immunodeficiency identified

After stroke and heart attack: Every year, between 250,000 and 300,000 people in Germany suffer from a stroke or heart attack. These patients suffer immune disturbances and are very frequently…

Wildfire danger to increase due to climate change

WSL Institute for Snow and Avalanche Research (SLF) researchers expect an elevated wildfire danger in the Alpine Foreland from 2040 onwards due to changing meteorological conditions. The danger currently remains…

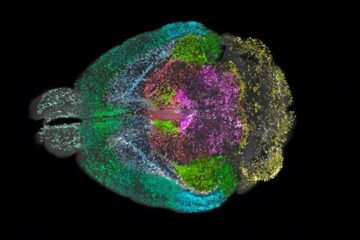

Advanced Brain Science Without Coding Expertise

Researchers at Helmholtz Munich and the LMU University Hospital Munich introduce DELiVR, offering a new AI-based approach to the complex task of brain cell mapping. The deep learning tool democratizes…