Scientists Make Magnetic Silicon, Advancing Spin Based Computing

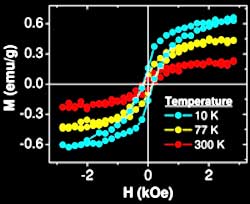

Ferromagnetic hysteresis loops taken at three temperatures measured from the Mn implated Si.

CNSE spintronics lab research shows silicon can maintain a permanent magnetic field above room temperature, which could help to develop more effective magnetic semiconductors and future spintronic devices

Silicon is best known as the material used to make semiconductor computer chips with integrated circuits. Today, scientists at the College of Nanoscale Science and Engineering (CNSE) at the University at Albany published research that could lay the foundation for using silicon to develop chips with magnetic properties, potentially impacting the development of electron-spin-based or “spintronic” devices.

Spintronics exploits the quantum mechanical property of electron spin, as well as its charge state. Potential spintronics applications include magnetic random access memory (MRAM), which could enable the development of computing devices that are always on, don’t require time to “boot up” and don’t require a traditional hard drive.

While semiconductor materials such as silicon are utilized for memory and central processing units, the permanent information in computers is stored in magnetized hard drives which utilize the spin of the electron.. Recent research has discovered that a semiconductor can be made magnetic by doping it with an impurity such as Mn. The resulting material or diluted magnetic semiconductor (DMS) combines the properties of magnetism used in permanent information storage with that of semiconductor memory and logic devices. DMS spintronic devices have the potential to operate at considerably higher speeds and consume less power than conventional devices.

The research conducted by CNSE Professor Vincent LaBella and Martin Bolduc, CNSE post-doctorate fellow, shows for the first time that silicon can be made “ferromagnetic” or permanently magnetic up to 127 C, well above where conventional devices operate. The researchers achieved this by implanting Mn into silicon up to a concentration of 1% per atom.

LaBella and Bolduc are both specialists in spintronics research. LaBella was the first spintronics specialist to attempt to “magnetize” silicon, using tools at the Albany NanoTech complex, home to CNSE. “The results are very exciting and open the door to silicon based spintronic devices that operate at or above room temperature,” said LaBella. “The samples were fabricated using standard semiconductor processing equipment available at Albany NanoTech to quickly get results, which were significantly positive.”

LaBella then joined forces with Bolduc for a more extensive experiment. The two implanted manganese into silicon in varying concentrations, then measured the magnetic properties with a SQUID magnetometer. They found the silicon was ferromagnetic above room temperature, or up to 127 degrees Celsius, opening up the possibility of its use in devices like personal computers, phones and PDAs. “These results indicate that the ferromagnetic exchange coupling in Si is very strong. Our future research is focused on understanding why this is so,” said Bolduc.

The research paper, entitled Above Room Temperature Ferromagnetism in Mn-ion implanted Si, was published in Physical Review B. Bolduc was lead author on the paper. For further information or to obtain a copy of the paper, contact Shonna Keogan at skeogan@uamail.albany.edu or vlabella@uamail.albany.edu.

About Albany NanoTech

One of the largest centers for nanotechnology research in the country, Albany NanoTech is home to the College of Nanoscale Science and Engineering (CNSE) and the New York State Center of Excellence in Nanoelectronics (NYSCEN) of the University at Albany-State University of New York. Its 450,000 square foot complex houses the only 200mm/300mm wafer facilities in the academic world, encompasses nanoelectronics, system-on-a-chip technologies, biochips, optoelectronics and photonics devices, closed-loop sensors and ultra-high-speed communication components.

With over 65,000 square fee of Class 1 capable 300 mm wafer cleanrooms, as well as on-site faculty and student researchers, Albany NanoTech provides corporate partners with a unique environment to pioneer, develop, and test new nanoscience and nanoengineering innovations.

Contact:

Shonna Keogan

College of Nanoscale Science and Engineering

University at Albany – SUNY

518-956-7201

skeogan@uamail.albany.edu

Media Contact

More Information:

http://www.albany.eduAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…