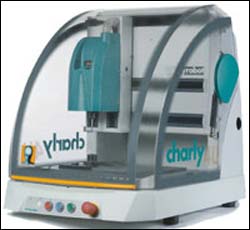

Charlyrobot launches 3D mini-milling Charly4U

Charlyrobot of France is launching its new generation of Computer Numerical Control (CNC) mini-milling machines, for compact 3D milling, called Charly4U. Charlyrobot has been a leading manufacturer of milling machines for more than 20 years. The company has local partners in the UK but is looking for distributors in the Nordic Region. Charlyrobot will be showcasing its technology at the Euromold trade show in Frankfurt in early December 2004.

Thanks to Charly4U, Charlyrobot is strengthening its leading position in the mini-milling machine market. With more than 700 units sold and distributed each year, Charly4U is fast becoming a manufacturer’s reference and a logical choice in the field of compact CNC milling.

As the first machine in its industry segment to be based on a steel framework, the Charly4U provides excellent rigidity for the perfect machining of soft metals, such as aluminium or brass, as well as soft materials, such as plastics or resin. With a movement of 310mm x 220mm x 160mm, the Charly4U can be used for all 2D and 3D industrial applications in a range of areas, including cutting, engraving, re-machining, jewellery, modelling, electronics, moulds, prototypes, prototype tools, and industrial design, among others.

The new milling-machine developed by Charlyrobot is a multipurpose machine with a long list of options – high-frequency spindle 1.1Kw, engraving spindle with tracking nose, micro-lubrication, and servo-brushless drive. It is equipped with a standard tool sensor for easy, rapid and reliable origin positioning. Maintenance is reduced to its simplest form, with a suction connector on the ’Z’ axis as well as built-in lubrication of ball screws and guide shoes.

Charly4U is economical, easy to use with fine-machining processes, and has an innovative design. The Charlyrobot range also includes an A2 format: the Charly2U with a movement of 600mm x 420mm x 280mm.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…