Fuel-cell microbes’ double duty: treat water, make energy

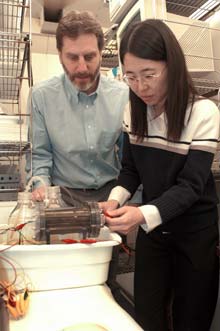

At their Pennsylvania State University lab, Bruce Logan watches as research colleague Hong Liu checks the circuit connections on the prototype microbial fuel cell. The jars behind it contain the "before" and "after" wastewater samples. <br>Credit: Greg Grieco, Penn State <br>

NSF ’sugar’ grant supports single-chamber prototype fed by wastewater

Something big may be brewing on the sewage treatment circuit thanks to a new design that puts bacteria on double-duty-treating wastewater and generating electricity at the same time.

The key is an innovative, single-chambered microbial fuel cell. The prototype is described in the online version of the journal Environmental Science & Technology (http://pubs.acs.org/journals/esthag/); the article will also appear in a future print version of ES&T.

A fuel cell operates akin to a battery, generating electricity from a chemical reaction. But instead of running down unless it’s recharged, the cell receives a constant supply of fuel from which electrons can be released. Typical fuel cells run off of hydrogen. In a microbial fuel cell, bacteria metabolize their food-in this case, organic matter in wastewater-to release electrons that yield a steady electrical current.

The single-chambered prototype, developed by researchers at Pennsylvania State University with support from the National Science Foundation (NSF), allows the process to work efficiently in wastewater.

In their paper, the researchers suggest that the improved design could usher in a “completely new approach” to wastewater treatment: “If power generation in these systems can be increased, microbial fuel cell technology may provide a new method to offset wastewater treatment plant operating costs, making advanced wastewater treatment more affordable for both developing and industrialized nations.”

An $87,000 grant from NSF’s Small Grants for Exploratory Research (SGER) program supported the project. Such SGER-called “sugar”-grants foster small-scale, innovative preliminary research on untested, novel ideas. They also sometimes fund quick- response research on natural disasters and other unanticipated events or support research to Scatalyze” emerging innovations.

The single-chambered microbial fuel cell is essentially a Plexiglass cylinder about the size of a soda bottle. Inside are eight graphite anodes (or negative electrodes), upon which the bacteria attach, and a hollow central cathode (or positive electrode). Electrons flow along a circuit wired from the anode to the cathode.

A steady flow of wastewater pumped into the chamber feeds the bacteria. Bacterial digestion of the wastewater’s organic matter unleashes electrons into the electrical circuit and positively charged hydrogen ions into the solution. Those ions reduce the solution’s oxygen demand, a key goal of wastewater treatment. The hydrogen ions also pass through a proton-exchange membrane to reach the cathode. Meanwhile, a hollow tube within the cylinder contains the cathode, which is exposed to air. At the cathode, oxygen from the air, hydrogen ions coming through the membrane and the electrons coming down the circuit combine to create water.

In other microbial fuel cells, microbes have been fed glucose, ethanol and other fuels, but, according to Bruce Logan, the Penn State professor of environmental engineering who leads the project, “Nobody has ever tried this with domestic wastewater. We’re using something thought to be completely useless.”

The single-chamber design is important, he said, because it facilitates a “continuous flow-through system,” a design consistent with existing treatment systems.

By introducing air passively through the tube within the cathode layer, this model also greatly reduces the need for more aggressive – and energy-demanding – aeration schemes to treat the wastewater. Thus, as it creates electricity, it also reduces the need for it.

Each year in the United States, about 33 billion gallons of domestic wastewater is treated at cost of $25 billion; much of it pays for energy. If the microbial fuel cell can be applied on a larger scale, it could significantly reduce the energy costs of wastewater treatment.

It’s not a small “if.”

“We’ve got to make it cheaper,” said Logan. “We can’t afford to use graphite rods on the anodes, Nafion as the protonexchange membrane, and platinum on the carbon cathode. But we’re already making progress on that. Substantially cheaper systems are just around the corner.”

Meanwhile, amid the slime on the anodes, countless and various bacteria play distinctive roles in the breakdown of the wastewater and creation of electricity. “This is a whole community reaction,” said Logan. “We’re just beginning to appreciate and understand the complex bacterial community needed to generate electricity from wastewater.”

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…