New catalyst paves way for cheap, renewable hydrogen

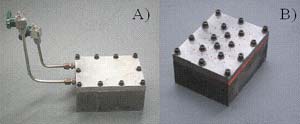

Photos of high-throughput reactor showing A) reactor with common headspace top plate (used for catalyst reduction) and B) reactor with isolated headspace plate (used for reaction and gas chromatograph analysis). <br>Credit: G. W. Huber, J. W. Shabaker, and J. A. Dumesic, University of Wisconsin-Madison; NSF, DOE

Scientists have developed a hydrogen-making catalyst that uses cheaper materials and yields fewer contaminants than do current processes, while extracting the element from common renewable plant sources. Further, the new catalyst lies at the heart of a chemical process the authors say is a significant advance in producing alternate fuels from domestic sources.

In the June 27 issue of the journal Science, James Dumesic, John Shabaker and George Huber, of the University of Wisconsin at Madison, report developing the catalyst from nickel, tin and aluminum and using it in a process called aqueous-phase reforming (APR), which converts plant byproducts to hydrogen. The process performs as well as current methods that use precious metals such as platinum, yet runs at lower temperatures and is much cleaner.

“The APR process can be used on the small scale to produce fuel for portable devices, such as cars, batteries, and military equipment, ” said Dumesic. “But it could also be scaled up as a hydrogen source for industrial applications, such as the production of fertilizers or the removal of sulfur from petroleum products.”

The team is now collaborating with scientists at Virent Energy Systems in Wisconsin as part of a National Science Foundation (NSF) Small Business Technology Transfer (STTR) grant to develop catalysts for generating fuels from biomass.

NSF is an independent federal agency that supports fundamental research and education across all fields of science and engineering.

Hydrogen is a “clean” fuel because when it burns, it combines with oxygen to form water; no toxic byproducts or greenhouse gasses are produced in the process. The APR process extracts hydrogen from a variety of biological sources, especially simple carbohydrates and sugars generated by common plants.

The precious metal platinum (Pt) is well known to be an excellent catalyst in a number of chemical reactions. It is one component in a car’s catalytic converter, for example, that helps remove toxins from automobile exhaust. Yet, platinum is rare and very expensive, costing more than $17 per gram (about $8,000 per pound).

Catalytic platinum (Pt) and nickel (Ni) stand out from other metals (such as copper or iron) because they process reaction molecules much faster. But pure nickel, unlike platinum, recombines the hydrogen product with carbon atoms to make methane, a common greenhouse gas. Dumesic and his colleagues tested over 300 catalysts to find one that could compete with platinum and perform in the APR process. Using a specially designed reactor that can test 48 samples at one time, the team finally found a match in a modified version of what researchers call a Raneynickel catalyst, named after Murray Raney, who first patented the alloy in 1927.

Raney-nickel is a porous catalyst made of about 90 percent nickel (Ni) and 10 percent aluminum (Al). While Raney-nickel proved somewhat effective at separating hydrogen from biomass-derived molecules, the researchers improved the material’s effectiveness by adding more tin (Sn), which stops the production of methane and instead generates more hydrogen. Relative to other catalysts, the Raney-NiSn can perform for long time periods (at least 48 hours) and at lower temperatures (roughly 225 degrees Celsius).

According to Dumesic, a substitute for platinum catalysts is essential for the success of hydrogen technology. “We had to find a substitute for platinum in our APR process for production of hydrogen, since platinum is rare and also employed in the anode and cathode materials of hydrogen fuel cells to be used in products such as cars or portable computers,” he said.

Additional support for this research was provided by the U.S. Department of Energy (DOE) and by the Materials Research Science and Engineering Center on Nanostructured Materials and Interfaces at the University of Wisconsin, a center established and supported by NSF.

NSF STTR Program Officer: Rosemarie Wesson, 703-292-8330, rwesson@nsf.gov

Principal Investigator: James Dumesic, 608-262-1096, dumesic@engr.wisc.edu

The National Science Foundation is an independent federal agency that supports fundamental research and education across all fields of science and engineering, with an annual budget of nearly $5.3 billion. National Science Foundation funds reach all 50 states through grants to nearly 2,000 universities and institutions. Each year, NSF receives about 30,000 competitive requests for funding, and makes about 10,000 new funding awards. The National Science Foundation also awards over $200 million in professional and service contracts yearly.

Receive official National Science Foundation news electronically through the e-mail delivery system, NSFnews. To subscribe, send an e-mail message to join-nsfnews@lists.nsf.gov. In the body of the message, type “subscribe nsfnews” and then type your name. (Ex.: “subscribe nsfnews John Smith”)

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

How blue-green algae manipulate microorganisms

Research team at the University of Freiburg discovers previously unknown gene that indirectly promotes photosynthesis. Cyanobacteria – also called blue-green algae – are known as the “plants of the ocean”…

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…