PRACE – the mobile production assistant

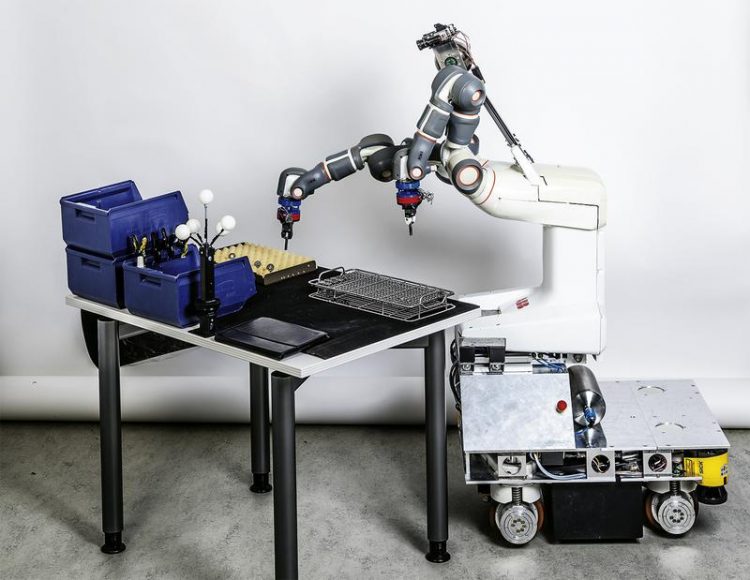

The PRACE demonstrator palletizes metal components for subsequent coating. source: Fraunhofer IPA

The concept follows the master-apprentice principle: learning by demonstration. The aim is to enable the worker to quickly and easily impart new skills to the mobile production assistant simply by demonstrating the relevant activities. At Automatica 2014, Fraunhofer IPA will show how the PRACE demonstrator works.

The goal of the EU research project PRACE is to develop a teachable, two-armed robot system for the partial automation of small batch production processes. The concept is based on the principle of learning by demonstration. The mobile production assistant learns from the worker how to carry out certain activities by itself. Similarly to a master-apprentice relationship, the worker shows the robot how to carry out the relevant tasks.

The mobile production assistant follows what the worker does and categorizes this new knowledge in its knowledge database. When the robot applies its newly acquired skill, the worker corrects and refines the robot’s actions as required until the desired result is achieved. At little expense, PRACE can be intuitively taught and quickly used for a variety of handling and manipulation tasks. This increases flexibility, cuts costs and makes the system especially attractive for small and medium-sized enterprises.

Safe and mobile two-armed manipulation for every user

For shorter set-up times, PRACE dispenses with protection systems and must therefore be operated at a lower speed of the individual robot arms. The two-armed robot provides a normal work output, while the combination of two-armed manipulation and mobile platform makes it possible for the output to be increased and for new applications in mass production to be cost-effectively automated. This is currently being trialled in production at Bosch as part of the PRACE project. Modular construction also allows the use of individual robot components and their combination with other systems.

The demonstrator from the PRACE project is based on Fraunhofer IPA’s rob@work 3 platform, ABB’s “dual-arm concept robot” and a tracking system from Magellium and DTI. In addition, the scientists from Fraunhofer IPA and Lund University are integrating a control for mobile manipulation to enable the planning and implementation of collision-free manipulation by both arms without the need for complex programming by the end user. Also, the robot system employs safe navigation methods to increase the workspace of compact manipulators: PRACE is capable of responding in real-time to dynamic changes in its environment in order to avoid collisions. “We have many years of experience in software development for the manipulation and navigation of autonomous systems. Fraunhofer IPA is focusing in particular on the development of components for localization and path planning in dynamic environments,” says Alexander Bubeck, Project Manager in the Robot and Assistive Systems department.

PRACE demonstrator in action

At Automatica 2014, PRACE will be used to carry out the preparations for a coating process: different parts for coating require simple and flexible programming of the mobile two-armed robot system. The process involves the following three steps:

• Demonstration of the new task:

The tracking system follows the movement of a teach-in tool used by the worker to demonstrate the desired motions of the system. There is also a database of robot actions (such as the recognition of components). A simulation is displayed during the teach-in process to show the worker the movements of the “robot apprentice” in real-time.

• Refinement phase:

After the teach-in phase, it may be the case that the PRACE demonstrator is incapable of executing the newly learned motion sequence to the required standard. In individual steps, therefore, the worker must further refine the robot’s motions using a tool-integrated camera system, force regulation or manual intervention to ensure that the robot is also able to carry out delicate operations, such as introducing a needle into a holder.

• Automated execution:

The new robot application can then be executed without intervention by the worker. The robot system autonomously improves its execution of the motions by, for example, using the second manipulator for execution or by shortening the travel trajectories.

PRACE stands for “Productive Robot Apprentice” and is an EU-funded research project (grant agreement no. 285380) as well as part of the 7th EU Framework Programme.

Partners in the project:

Fraunhofer IPA (Germany), Robert Bosch GmbH (Germany), Teknologisk Institut (Denmark), Lund University (Sweden), Magellium SAS (France) and ABB AG (Germany).

More at Automatica – 6th International Trade Fair for Automation and Mechatronics

3 to 6 June 2014

New Trade Fair Centre Munich

Hall A4 | Stand 530

Contact

Dipl.-Ing. Alexander Bubeck, phone +49 711 970-1314, alexander.bubeck@ipa.fraunhofer.de

http://www.automatica-munich.com

http://prace-fp7.eu/

http://www.ipa.fraunhofer.de

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…