Paraffins to cut energy consumption in homes

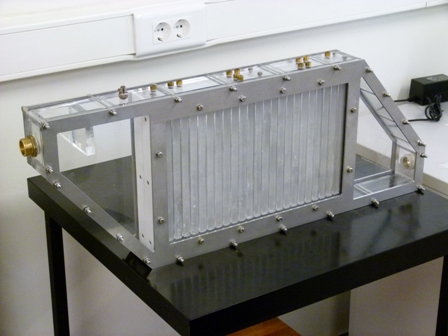

View of the thermal energy storage prototype

40% of the total consumption of energy in Europe takes place in buildings, so reducing this consumption is becoming increasingly important. Integrating renewables into the energy supply for buildings is a further step towards moving towards this aim.

The UPV/EHU research group ENEDI has developed a modular device based on paraffins that allows thermal energy to be stored, thus reducing the total volume of the system by 50% with respect to storage by means of water, traditionally used in buildings.

Thermal energy storage is a common strategy in energy production systems in which the period of production does not coincide with that of consumption. This happens with the production of hot water by means of solar thermal panels, for example; here, hot water is produced during sunlight hours when demand is lower.

It is also the case in residential cogeneration, where heat and electrical power are simultaneously generated but not so demand. In both cases, storing the heat allows production to be decoupled from demand, thus making the integration of these technologies into buildings more flexible. Here, it is normal for periods of energy production not to coincide with those when it is consumed.

Water tanks have been traditionally used to store heat. “They work well,” explained Álvaro Campos, a researcher on the project, “and water is very cheap, but large volumes are needed to achieve significant heat storage, which restricts their integration into homes, where the availability of space is very limited.”

The UPV/EHU research group ENEDI has developed a prototype with 50% less volume and more flexible in terms of design; it has a prismatic shape, is easy to integrate into buildings and offers optimum use of space. What is more, its modular nature allows the design to be easily changed.

The system is based on the use of latent heat from the solid-liquid phase change of materials known as PCMs (Phase Change Materials). “When we heat these materials they have the capacity, once they reach their phase change temperature, to start changing their state; and by keeping the temperature practically constant, they allow a very high quantity of energy to be stored; that way, we can achieve much greater energy density with smaller heat losses into the atmosphere,” explained Campos.

The device uses a commercial paraffin that melts at around 60 ºC. “It is very stable and has a long service life,” pointed out Campos. The paraffin is encapsulated inside aluminium plates which are arranged in such a way that channels are formed between them.

The thermal loading and unloading process is carried out by making water circulate through these channels, so the hot water yields heat to the plates during the loading process and melts the encapsulated material; conversely, cold water is made to circulate through the channels so that the stored heat is recovered and the paraffin solidifies. Campos' proposal solves one of the problems of PCMs which, owing to their low thermal conductivity, tend to take a very long time to yield the heat they have accumulated. “Our design is based on very thin metal plates which allow the heat to be extracted at a speed similar to that of water tanks,” he concluded.

According to Campos, one of the most attractive aspects of the system lies in its compact, modular nature. Water tanks need to be cylindrical and slim (tall and thin) if they are to function optimally. “We can achieve much more compact, prismatic shapes that can be fitted into any corner, even inside a false ceiling,” he remarked. “All this makes our proposal more than just an alternative to the water tank, because it offers the possibility of fitting a device for storing thermal energy in places and in applications where, owing to a lack of space, the fitting of a water tank may not be feasible,” added Campos.

Right now, work is being done to build a full-scale prototype that will be integrated into an experimental facility of the Quality Control in Building Lab (LCCE) of the Government of the Basque Autonomous Community, “to study how the equipment responds under actual operating conditions”.

Campos is optimistic about the competitiveness of the device. “We have something that could offer sufficient technical advantages as it is an attractive proposal irrespective of the final price.” The group is already working on other potential PCMs that allow greater storage capacity and are cheaper; they include fatty acids and other organic materials.

Additional information

Alvaro Campos-Celador is a Doctor of Engineering, researcher and lecturer at the UPV/EHU-University of the Basque Country and member of the university's consolidated research group ENEDI (Energy in Building). The team is led by Jose María Sala-Lizarraga, Professor of Thermodynamics in the UPV/EHU's Department of Thermal Machines and Engines at the Faculty of Engineering in Bilbao. The research was mainly conducted at the UPV/EHU's University School of Mining and Public Works Engineering and at the Quality Control in Building Lab of the Government of the Basque Autonomous Community, where the Thermal Area is currently being led by ENEDI. This research is registered within the microTES project (ENE2012-38633-C03), in which the University of Oviedo and the University of La Rioja are also participating.

References

1. A. Campos-Celador, G. Diarce, J. Terés-Zubiaga, T. Bandos, A. García-Romero, L.M. López, J.M. Sala, Design of a Finned Plate Latent Heat Thermal Energy Storage System for Domestic Applications, Energy Procedia, 48 (2014) 300-308.

2. Campos-Celador, G. Diarce, I. González-Pino, J.M. Sala, Development and comparative analysis of the modeling of an innovative finned-plate latent heat thermal energy storage system, Energy, 58 (2013) 438-447.

Patents

As a result of this research, an international patent is currently being applied for: Modular latent thermal storage unit (WO 2014016456 A1)

Inventors: ÁLVARO CAMPOS CELADOR, JOSÉ MARÍA SALA LIZARRAGA, LUIS ALFONSO DEL PORTILLO VALDÉS. http://www.google.com/patents/WO2014016456A1?cl=es

Media Contact

More Information:

http://www.ehu.es/All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…