Optimal Design for Photvoltaic Plants

<br>

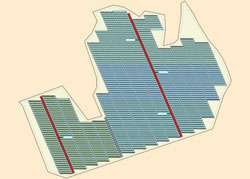

Such power plants have to be customized in line with the given terrain, weather conditions, customer requirements, and the types of solar modules to be used in them. PVplanet (PV Plant Engineering Toolbox) from Siemens generates hundreds of different plant layouts within a just a few seconds.

It can also analyze conflicting planning objectives such as electrical output and costs, and the effect they will have on one another. As a result, the software reduces planning times by around 80 percent as compared to the common process to date of creating individual layouts and comparing them. Siemens Energy has been testing an initial version of PVplanet since April 2012.

The share of electricity generated by photovoltaic power plants on roofs or in open spaces is increasing. Installed photovoltaic output tripled worldwide between 2009 and 2011 alone. The solar cells used in photovoltaic plants convert sunlight directly into electrical energy. Planning large facilities is a very complex process, however.

For example, if you spread the solar modules far apart, you can reduce the shadow each module will cast on the others, thereby increasing efficiency. This causes a problem, however, because increasing the distance between modules means fewer installed modules and thus less overall output. Planning engineers therefore have to make technical and economic compromises for a large number of parameters, while still meeting customer requirements regarding aspects such as minimum output or cost limits.

In order to make this planning easier, Siemens Energy and the Fraunhofer Institute for Industrial Mathematics (ITWM) have developed the PVplanet planning tool, which simultaneously calculates the cost and potential output of a large number of possible designs and then identifies the best solution. The software is based on mathematical algorithms specially developed by ITWM, as well as the wealth of experience Siemens has in designing solar power plants.

Engineers who use the software initially enter basic conditions such as topography and weather. After that, they select module and inverter types and can also alter or limit parameters like angles of inclination, service access ways, and component costs. The software uses the results to calculate the electricity production costs and thus the potential profitability of a given facility layout.

PVplanet will made available to the engineering teams at Siemens' regional units and be further refined this fall.

Media Contact

More Information:

http://www.siemens.com/innovationnewsAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…