Optical nano-tweezers take over the control of nano-objects

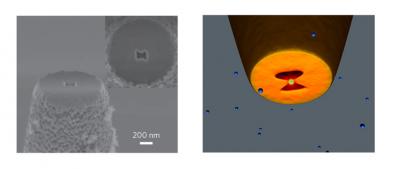

The image on the left is an electron beam microscopy image of the extremity of the plasmon nano-tweezers. The image on the right is a sketch illustrating the trapping of a nanoparticle in the bowtie aperture. Credit: Institute of Photonic Sciences

As science and technology go nano, scientists search for new tools to manipulate, observe and modify the “building blocks” of matter at the nanometer scale. With this in mind, the recent publication in Nature Nanotechnology in which ICFO researchers demonstrate for the first time the ability to use near-field optical tweezers to trap a nano-size object and manipulate it in the 3 dimensions of space, is an exciting achievement. Romain Quidant, ICREA Professor and leader at ICFO of the Plasmon Nano-Optics research group comments that “this technique could revolutionize the field of nanoscience since, for the first time, we have shown that it is possible to trap, 3D manipulate and release a single nano-object without exerting any mechanical contact or other invasive action”.

Imagine an elephant trying to grab an object the size of a needle with its gigantic hoof? Clearly this would be a tremendous if not impossible challenge because of the elephant's enormous size in comparison to that of the needle. Now imagine that our needle is a single molecule or tiny object about the size of a few nanometers and we, with our conventional tools, need to trap it and manipulate it in in order to, for example, understand its implication in the development of a disease. We have the same problem, first because a conventional optical microscope is not capable of visualizing a single molecule and second, because the physical limitations of our conventional tweezers are simply not capable of grasping or manipulating such small objects.

Invented in Bell Labs in the 80's, the original optical trapping demonstrated great capability to trap and manipulate small objects of micrometer size dimensions using laser light. By shining a laser light through a lens, it is possible to focus light in a tiny spot, creating an attractive force due to the gradient of the light intensity of the laser and thus attracting an object/specimen and maintaining it in the spot/focus.

While Optical tweezers have changed forever the fields of both biology and quantum optics, the technique has considerable limitations, one of which being its inability to directly trap objects smaller than a few hundreds of nanometers. This drawback prompted the pursuit of new approaches of nano-tweezers based on plasmonics, capable of trapping nano-scale objects such as proteins or nanoparticles without overheating and damaging the specimen. A few years ago, ICFO researchers demonstrated that, by focusing light on a very small gold nano-structure lying on a glass surface which acts as a nano-lens, one can trap a specimen at the vicinity of the metal where the light is concentrated. This proof of concept was limited to demonstrate the mechanism but did not enable any 3D manipulation needed for practical applications.

Now researchers at ICFO have taken this a crucial step further by implementing the concept of plasmonic nano-tweezers at the extremity of a mobile optical fiber, nano-engineered with a bowtie-like gold aperture. Using this approach, they have demonstrated trapping and 3D displacement of specimens as small as a few tens of nanometers using an extremely small, non-invasive laser intensity. Central to the great potential of this technique is that both trapping and monitoring of the trapped specimen can be done through the optical fiber, performing the manipulation of nano-objects in a simple and manageable way outside of the physics research lab.

This technique opens a plethora of new research directions requiring non-invasive manipulation of objects at the single molecule/virus level. It is potentially attractive in the field of medicine as a tool to further understand the biological mechanisms behind the development of diseases. Likewise, it holds promise in the context of nanotechnologies to assemble future miniature devices, among other exciting potential applications.

This research was made possible thanks to the financial support of the European Research Council through the grant Plasmolight; no. 259196 and Fundació privada CELLEX.

Reference: J. Berthelot, S. S. Acimovic, M. L. Juan, M. P. Kreuzer, J. Renger and R. Quidant, Three-dimensional manipulation with scanning near-field optical nanotweezers, DOI: 10.1038/NNANO.2014.24

About ICFO

ICFO-The Institute of Photonic Sciences was created in 2002 by the government of Catalonia and the Technical University of Catalonia as a center of research excellence devoted to the science and technologies of light with a triple mission: to conduct frontier research, train the next generation of scientists and technologists, and provide knowledge and technology transfer. In recognition of research excellence, ICFO was granted the Severo Ochoa accreditation by the Ministry of Science and Innovation. In addition, ICFO has secured the number one position worldwide among Physics research institutes in the Mapping Excellence study led by the Administrative Headquarters of the Max Planck Society ('Ranking and mapping of universities and research-focused institutions worldwide based on highly-cited papers').

Research at ICFO targets the forefront of science and technology based on light with programs directed at applications in Health, Renewable Energies, Information Technologies, Security and Industrial processes, among others. The center currently hosts 300 professionals including researchers and PhD students, working in 60 laboratories. All research groups and facilities are located in a dedicated 14.000 m2 building situated in the Mediterranean Technology Park in the metropolitan area of Barcelona.

Researchers at ICFO publish in the most prestigious journals and collaborate with a wide range of companies around the world. The Client Liaison Program at ICFO, which includes members of a large number of local and international companies, aims to create synergies between ICFO and the industrial sector. The institute actively promotes the creation of spin-off companies by ICFO researchers. The institute participates in a large number of projects and international networks of excellence. Foundation Cellex finances the NEST program at ICFO which makes possible many ambitious frontier research projects.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…