Labs characterize carbon for batteries

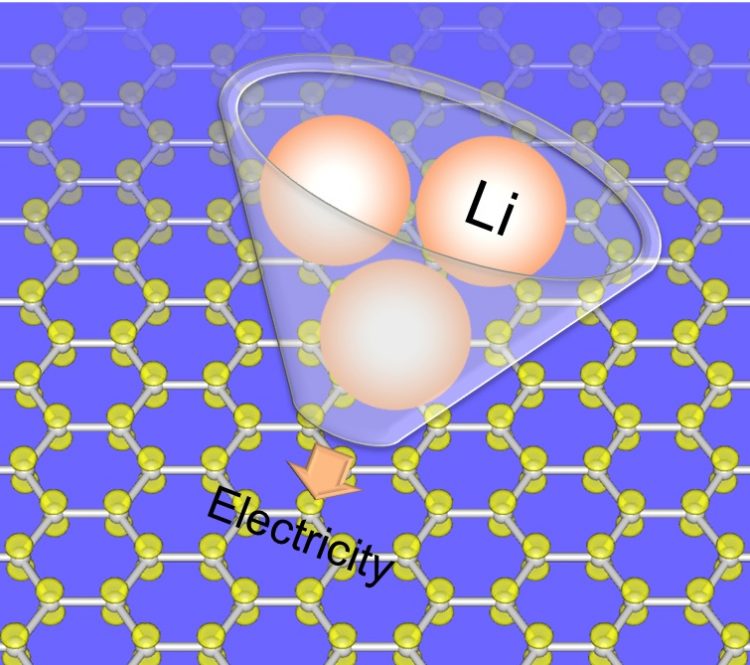

New work by scientists at Lawrence Livermore National Laboratory and Rice University details the binding properties of lithium ions to various types of carbon that may be used for lithium-ion batteries. The “universal descriptor” they found has the potential to speed the development of materials for commercialization. (Credit: Yuanyue Liu/Rice University)

Lithium-ion batteries could benefit from a theoretical model created at Rice University and Lawrence Livermore National Laboratory that predicts how carbon components will perform as electrodes.

The model is based on intrinsic electronic characteristics of materials used as battery anodes. These include the material’s quantum capacitance (the ability of the material to absorb charge) and the material’s absolute Fermi level, which determines how many lithium ions may bond to the electrodes.

Subtle changes in the structure, chemistry and shape of an electrode can significantly alter how strongly lithium ions bond to it and affect a battery’s capacity, voltage and energy density. The researchers found a universal correlation between these properties and a simple quantity they called the “states-filling work” that should allow scientists to fine-tune electrodes.

The research appears in the journal Physical Review Letters. Lawrence Livermore scientist Brandon Wood and Rice theoretical physicist Boris Yakobson led the study.

Fine-tuning becomes critically important as materials scientists test more 2-D materials like graphene and nanotubes for use as electrodes. The materials offer vast surface area for ions to bind to in a compact package, Yakobson said.

“This work emphasizes the role of quantum capacitance,” he said. “Capacitance in a battery is usually defined by the configuration of your electrodes; people think about this as the distance between the plates.

“But if the plates become very close and the electrodes and electrolyte are tight, then quantum capacitance becomes the limiting parameter.”

“The Fermi level of the electrode material is also important,” said Rice graduate student Yuanyue Liu, the paper’s lead author. “The lower it is, the stronger lithium will bind.”

Liu and Lawrence Livermore staff scientist Brandon Wood were looking for a “descriptor,” a characteristic that would capture the essential physics of interactions between lithium and a variety of carbon materials, including pristine, defective and strained graphene, planar carbon clusters, nanotubes, carbon edges and multilayer stacks.

“That descriptor turned out to be the ‘states-filling work’ – the work required to fill previously unoccupied electronic states within the electrode,” Liu said.

“Generally speaking, a descriptor is an intermediate property or parameter that doesn’t give you what you really want to know, but correlates well with the material’s final performance,” Yakobson said.

“The descriptor connects to properties that may be quite complex,” he said. “For instance, you can judge people’s physical strength by how tall they are or by weight. That’s easy to measure. It doesn’t exactly tell you how strong the person will be, but it gives you some idea.”

Based on the descriptor, the researchers were able to evaluate various carbon materials. Specifically, they found materials like defective or curved graphene were good candidates for anodes, as their energy profiles allowed more lithium ions to bind. Ultimately, their work suggested a set of binding guidelines for carbon anodes.

“These allow us to quickly evaluate material performance without doing electrochemical tests or expensive computations,” Liu said.

“The fact that our descriptor predicts the performance of such a wide variety of materials is surprising,” Wood said. “It means the underlying physics is really very similar, even if the structure, morphology, or chemistry differs from one candidate to the next. It’s really a very simple and elegant finding that could accelerate design and discovery.”

Yakobson noted the work is in line with the Materials Genome Initiative (MGI), which aims to double the speed and reduce the cost of developing advanced materials by providing these kinds of tools. Earlier this year, Rice’s George R. Brown School of Engineering hosted a workshop on the MGI initiative, one of four held around the country.

Yakobson is Rice’s Karl F. Hasselmann Professor of Materials Science and NanoEngineering, a professor of chemistry and a member of the Richard E. Smalley Institute for Nanoscale Science and Technology.

Lawrence Livermore National Laboratory and the Department of Energy supported the research.

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,920 undergraduates and 2,567 graduate students, Rice’s undergraduate student-to-faculty ratio is just over 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice has been ranked No. 1 for best quality of life multiple times by the Princeton Review and No. 2 for “best value” among private universities by Kiplinger’s Personal Finance.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Making diamonds at ambient pressure

Scientists develop novel liquid metal alloy system to synthesize diamond under moderate conditions. Did you know that 99% of synthetic diamonds are currently produced using high-pressure and high-temperature (HPHT) methods?[2]…

Eruption of mega-magnetic star lights up nearby galaxy

Thanks to ESA satellites, an international team including UNIGE researchers has detected a giant eruption coming from a magnetar, an extremely magnetic neutron star. While ESA’s satellite INTEGRAL was observing…

Solving the riddle of the sphingolipids in coronary artery disease

Weill Cornell Medicine investigators have uncovered a way to unleash in blood vessels the protective effects of a type of fat-related molecule known as a sphingolipid, suggesting a promising new…