Improvements in fuel cell design

Researchers in the renewable energy sector are working hard in this respect. In this context, researchers in the UPV/EHU's Department of Applied Chemistry are exploring possible solutions to improve the efficiency of mobile devices like, for example, mobile phones, laptop computers and vehicles. In other words, they are designing new ways of obtaining energy in a cleaner, safer and more affordable way.

Fuel cells are totally appropriate systems for substituting the batteries of mobile phones, laptop computers and vehicles. They turn the energy resulting from the combining of hydrogen and oxygen into electrical power, with water vapour being the only waste product. In other words, they generate energy in the same way that batteries do, but they do not contaminate.

However, if these fuel cells are to produce energy, they need an external supply of hydrogen, and right now storing hydrogen safely poses difficulties. That is why what could be a good option is to use a piece of infrastructure that produces gaseous hydrogen inside the cell itself.

In these cases methanol is normally used as the raw material. And methanol is in fact one of the most important fuels used to produce hydrogen. For example, instead of powering mobile phones, laptop computers and vehicles with hydrogen, methanol can be added to them so that the methanol is turned into hydrogen depending on the needs of the device. In the end, the process is the same even though it takes place in two phases.

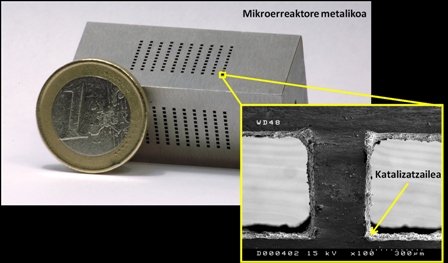

A special piece of infrastructure has been designed in the course of this research work: a reactor comprising micro-channels. And a micro-reactor a hundred times smaller than a conventional reactor system has been developed. And the size of the reactor is in fact crucial in the case of all these mobile devices.

“It is no easy task developing a reactor comprising micro-channels,” explained Oihane Sanz, a researcher at the UPV/EHU's Department of Applied Chemistry. “The choice of materials, the machining of the micro-channels, the assembly of the system and the catalytic coating, among other things, have to be carried out with the utmost care.”

They have seen that these reactors comprising micro-channels contribute towards improving the heat transfer to convert the methanol into hydrogen. Thanks to this, the reaction temperature is properly controlled and, therefore, the hot spots in which the carbon monoxide (CO) arises are minimized. If CO is produced together with the hydrogen, the fuel cell can in fact become contaminated. As a result of this contamination, the cell will not function properly and, therefore, the production of energy is halted.

A stable catalyst

Likewise, choosing a catalyst and using a suitable method of depositing it are indispensable conditions for the reaction to take place as efficiently as possible. “One of the biggest difficulties of these reactors made up of micro-channels is inserting the catalyst into these channels that are so small. That is why the aim of this research has been to design a stable catalyst and insert it into the system in the best way possible. In the processes to obtain hydrogen from methanol, palladium (Pd) catalysts are used, and this is precisely what the researchers have done in this case. Specifically, they used PdZnO. Often, “when incorporating the catalysts into reactors made up of micro-channels, the characteristics of the catalysts are lost. However, with the catalysts used in this study, we have managed not only to maintain their characteristics but also carry out the process easily”.

With the right infrastructure and catalyst, the micro-reactor designed by the UPV/EHU researchers produces 30 LH2/h.g; the conversion of methanol is 95%, and that of carbon monoxide (CO) less than 1%. “It is very important to control the production of carbon monoxide as it could contaminate the fuel cell,” stressed Sanz. “Systems that produce a bigger quantity of hydrogen (12-50 LH2/h.g) have been documented, but the conversion of the methanol is lower (80 %, and, in some cases, 4 %), and, what is more, marginal products are generated,” added Sanz. In the end, this design “enables us to develop a cleaner, safer and less costly process,” concluded Sanz.

Additional information

The research was conducted by the Department of Applied Chemistry of the UPV/EHU's Donostia-San Sebastian Faculty led by Prof Mario Montes. Also collaborating were the group led by Prof José Antonio Odriozola of the University of Seville (ICMS-University of Seville Institute of Materials Sciences, US-CSIC-Spanish National Research Council Mixed Centre) and the group led by Profs Gurutze Arzamendi and Luis M. Gandia of the NUP/UPNA-Public University of Navarre.

Bibliographical reference

F.J. Echave, O. Sanz, M. Montes. “Washcoating of micro-channel reactors with PdZnO catalyst for methanol steam reforming” Applied Catalysis A: General: 159 -167 2014.

Media Contact

More Information:

http://www.ehu.es/All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…