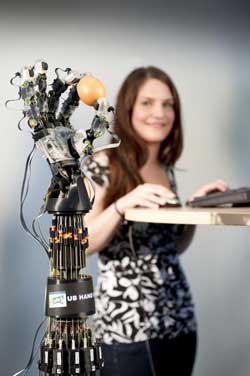

Whether grasping Easter eggs or glass bottles – this robotic hand uses tact

robotic hand<br>Photo: Markus Breig

Researchers at Saarland University together with associates in Bologna and Naples have developed a robotic hand that can accomplish both tasks with ease and yet including the actuators is scarcely larger than a human arm. This was made possible by a novel string actuator, making use of small electric motors to twist strings. The robotic hand is thus powerful yet delicate and could one day be deployed as a helper around the house or in catastrophic scenarios.

„We wanted to impart our robotic hand with a broad spectrum of human traits. Its artificial muscles should be able to deliver enormous forces by simple and compact means“, explains Chris May, scientist at Saarland University’s Laboratory of Actuation Technology. The robotic hand was recently presented during a meeting at the Forschungszentrum Informatik in Karlsruhe. It is an example of some of the new steps taken in robotic research within the scope of the European project DEXMART. Over the past four years international scientists developed various concepts, especially focussed on increasing the versatility with which two-arm robots can be implemented. The European Union sponsored the research consortium to the sum of 6.3 million Euros.

„When robots help around the house or should save people from a burning building, they need to have hands which can grasp with strength but at the same time gently“, explains Hartmut Janocha, Professor of Process Automation at Saarland University. The challenge lies in trying to make the necessary technology fit within the robotic arm such that it does not differ significantly from a human arm in terms of size and form. „We came up with a simple, yet extremely effective idea: using strings that are twisted by small, high-speed motors, we are able to exert high tensile forces within a compact space“, explains mechatronic researcher May. The sensorised and controlled robotic hand is able to touch diverse objects, to grasp and lift them and place them gently in a new position. Chris May demonstrated this in Karlsruhe with a delicate Easter egg and a heavy glass bottle.

Extremely strong polymer strings enable the Saarbrücken researchers to lift a five kilogram load by 30 mm within a split second, making use of a small electric motor and a 20 cm long string. „Each robotic finger, which like a human finger is comprised of three segments, can be controlled precisely by means of the individual tendons “, describes Chris May the novel miniature actuator. The mini electric motors run at high speed and a small torque on the order of five Newton-millimetres. „The capability of the robotic hand is so near to that of humans that the vision of robots as personal assistants in the household, in the operating room as well as in industrial settings is becoming ever more realistic. We presume that the combination of small electric motors with twisted string is interesting for other applications as well“, the researcher reckons.

Complementing the topics of robotic hand design, actuation and sensor development, the other DEXMART research teams addressed topics of programming by demonstration, object grasping and manipulation as well as human-robot interaction. A total of eight universities and research institutes in Germany, France, Italy and Great Britain participated in the European funded research initiative.

Please address questions to:

Chris May

Lehrstuhl für Antriebstechnik (LAT)

Universität des Saarlandes

Tel.: 0681 / 302-71690

may@lat.uni-saarland.de

Notice for radio journalists: It is possible to hold telephone interviews with the scientists at Saarland University in studio quality by means of the ISDN audio codec. Please contact the press office (+49 681 / 302-3610) to express interest in holding interviews.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…