Generating power from industrial waste heat

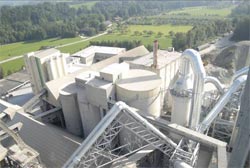

Suedbayerische Portland Zementwerk Gebr. Wiesboeck & Co. GmbH, Rohrdorf, Germany

Südbayerische Portland Zementwerk Gebr. Wiesböck & Co. GmbH, Rohrdorf, Germany, is building near Rosenheim the first German power plant to use hot waste gas from cement production to generate electricity. A consortium of the Siemens Industry Solutions Division and Kawasaki Plant Systems, Ltd. was commissioned to set up the new plant with a waste heat recovery system. Upon completion in April 2012, the plant will cover one-third of the cement works' power requirements.

Südbayerisches Portland Zementwerk GmbH is part of the Rohrdorfer Baustoffgruppe. The company manufactures cement, transit-mixed concrete, concrete goods and prefabricated concrete parts at 40 production locations in Germany and Austria. The new power plant at the cement works in Rohrdorf will use the hot waste gas from the rotary kiln and the clinker cooler, as well as the residual heat from the chimney, to generate electricity. The power plant is sized to include the future waste heat from the chloride bypass. This innovative, highly efficient and environmentally friendly project is being supported by the Federal Ministry for the Environment within the framework of its environmental innovation program. With the construction of a new raw mill and a dedusting facility, the cement works in Rohdorf has already made an important contribution to climate protection.

Kawasaki Plant Systems, Ltd. and Siemens formed a consortium to construct the plant, in order to keep responsibility for the water/steam cycle with a single party. Beforehand, all possible heat sources in the production facility were analyzed and evaluated in close cooperation with Portland Zementwerk GmbH. The cement plant in Rohrdorf, Germany, is attending to planning and execution of all civil works, steel construction and piping, along with integration into the existing production facility. Siemens is supplying the electrical equipment and instrumentation and control, as well as the steam turbine and the generator. Supervision of construction and commissioning are also comprised in the Siemens contract. Kawasaki is providing the overall plant design and engineering for the water/steam cycle. The pressure parts of the boiler, the feed water pre-heater on the clinker cooler, and the air condenser for the steam turbine are the components Kawasaki is supplying. The waste heat recovery boiler features horizontal gas passage. Dust is removed from the vertically arranged heat exchanger tubes by means of the proven and patented Kawasaki hammering mechanism.

The new power plant with a capacity of 6.8 megawatts will generate some 50,000 megawatt hours of electrical energy per annum. That is equivalent to the power consumption of 34,600 people or 16,400 households. The generation of power from this industrial waste heat will also eliminate some 31,500 tons of carbon dioxide per year. This increases energy efficiency in production and reduces CO2 emissions.

Solutions for exploiting waste heat are part of the Siemens environmental portfolio, with which the company achieved sales of some €23 billion in fiscal 2009. That makes Siemens the world's largest supplier of environmentally sustainable technology. In the same period, customers saved 210 million tons of carbon dioxide by using products and solutions from Siemens. This corresponds to the current annual combined CO2 emissions of New York, Tokyo, London and Berlin.

The Siemens Industry Sector (Erlangen, Germany) is the worldwide leading supplier of environmentally friendly production, transportation, building and lighting technologies. With integrated automation technologies and comprehensive industry-specific solutions, Siemens increases the productivity, efficiency and flexibility of its customers in the fields of industry and infrastructure. The Sector consists of six divisions: Building Technologies, Drive Technologies, Industry Automation, Industry Solutions, Mobility und Osram. With around 207,000 employees worldwide (September 30), Siemens Industry achieved in fiscal year 2009 total sales of approximately €35 billion.

The Siemens Industry Solutions Division (Erlangen, Germany) is one of the world's leading solution and service providers for industrial and infrastructure facilities comprising the business activities of Siemens VAI Metals Technologies, Water Technologies and Industrial Technologies. Activities include engineering and installation, operation and service for the entire life cycle. A wide-ranging portfolio of environmental solutions helps industrial companies to use energy, water and equipment efficiently, reduce emissions and comply with environmental guidelines. With around 31,000 employees worldwide (September 30), Siemens Industry Solutions posted sales of €6.8 billion in fiscal year 2009.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…