Conceptual Infrared Heat – The New MAX Infrared Oven for Efficient Industrial Solutions

MAX Infrared ovens combine infrared radiation with convection and optimum reflection Copyright Heraeus Noblelight, Hanau 2014

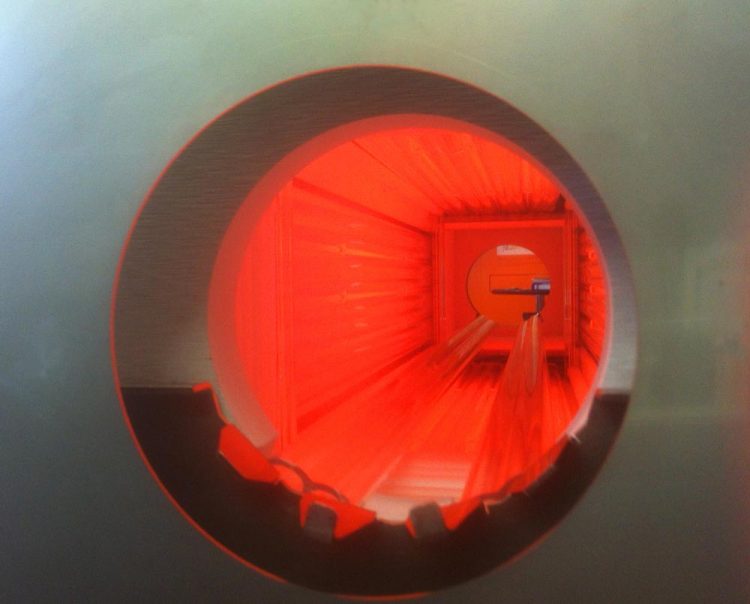

Heraeus Noblelight has developed a new infrared oven – MAX – for high temperature heating processes. These new ovens combine infrared radiation with convection and optimum reflection. As such, they are superior to conventional industrial ovens. They are matched exactly to the heating process, so making it very stable. This helps to increase capacity and improve quality and the efficient ovens save space, time and energy.

MAX – precisely tailored for maximum customer benefit

Juergen Weber, development project manager at Heraeus Noblelight, explains, “As they reach their maximum temperature within a very short time, the new MAX ovens flexibly meet customer requirements.’ The new oven can achieve a maximum product temperature of 900°C in less than ten minutes and can also cool down in less than ten minutes.This allows fast product change-over. The oven can also be used in both continuous and batch operation.

All MAX infrared ovens feature a compact construction, which utilizes the energy significantly more efficiently, because the infrared radiation is optimally reflected within the oven, which also uses natural convection. As a result, the process time can be reduced, significantly increasing energy efficiency and lowering operating costs.

MAX Infrared ovens – extremely energy-efficient

MAX infrared ovens are currently used in Heraeus’ in-house application center for intensive trials on customer materials. “Coating metal plates or glass tempering are particularly energy-intensive processes creating enormous electricity costs,” continues Juergen Weber. “Our tests show that this new design of oven can save a third of this energy or more.” One of the ovens, with a heated length of 700mm and a chamber cross section of 150x150mm achieves the maximum emitter temperature in less than a minute when working in a continuous process. In constant operation at a holding temperature of 900°C, a holding power of around 3kW is all that is required because of the exceptional energy-efficiency. In addition, it has been shown that an extremely good homogeneity can be achieved with a temperature difference within the product of only +/- 2°C.

Advantages of QRC® Material Over Standard Ovens

Tests demonstrate clear advantages over standard ovens, which use fireclay as the insulation material. In MAX infrared ovens quartz glass materials with QRC® nano-reflectors (QRC = quartz reflective coating) are used exclusively inside the oven. The QRC® reflector, developed by Heraeus, features opaque, white quartz glass. Its nanostructure imparts a diffuse reflective capability to the material, resulting in a very high homogeneity of the temperature field.

Quartz glass is extremely heat-resistant and widely resistant to the attack of acids and other aggressive substances. It has excellent mechanical stability, even at very high temperatures.

From simulation to final solution

MAX infrared ovens enable system solutions. Computer simulations at the design phase help to create an energy-efficient heating process. MAX oven elements can be arranged one after the other in modular fashion and individually controlled, allowing fast product change-over. In addition, the ovens can be easily connected with conveyor systems.

Infrared emitters can be precisely matched to product and process, saving energy and cost. Infrared heating should always be considered for heating processes which have important requirements in terms of space, time or quality. Heraeus offers infrared emitters, controllers and handling solutions to meet these requirements.

The precious metals and technology group Heraeus headquartered in Hanau, Germany, is a global, family company with over 160 years of tradition. Our businesses include precious metals, materials and technologies, sensors, biomaterials and medical products, quartz glass, and specialty lighting sources. With product revenues of € 4.2 billion and precious metal trading revenues of € 16 billion in 2012, Heraeus has around 12,200 employees in more than 100 companies worldwide and holds a leading position in its global markets.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China and Australia, is one of the technology- and market-leaders in the production of specialist light sources. In 2012, Heraeus Noblelight had an annual turnover of 92.5 Million € and employed 715 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques.

Heraeus Noblelight acquired the Fusion UV Systems Group, headquartered in Gaithersburg, Maryland, USA, on 31 January 2013.

For further information, please contact: Technical: Heraeus Noblelight GmbH Reinhard-Heraeus-Ring 7 D-63801 Kleinostheim Tel +49 6181/35-8545, Fax +49 6181/35-16 8545 E-Mail hng-infrared@heraeus.com Press: Dr. Marie-Luise Bopp Heraeus Noblelight GmbH, Marketing Tel +49 6181/35-8547, Fax +49 6181/35-16 8547 E-Mail marie-luise.bopp@heraeus.com www.heraeus-noblelight.com/infraredMedia Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…