Computer Model Optimizes Wind Farm

When the wind causes the huge rotors to turn, it generates turbulence, which interferes with the operation of the wind turbines in the rows to the rear. To address this problem, the new software program simulates the behavior of the entire wind farm and adjusts the individual turbines’ performance with one another.

According to experts, this could increase the energy yield by several percent, as reported in the latest issue of the research magazine “Pictures of the Future”. The same method could also be used to reduce the mechanical stress on the wind turbines, thus extending their service life. The software is currently undergoing endurance testing at Sweden’s Lillgrund wind farm.

Offshore wind turbines are gigantic; the 48 Siemens turbines in Lillgrund tower 115 meters above the water’s surface. The rotors have a diameter of 93 meters, and the wind causes them to create kilometer-long trails of turbulence. As a result, turbines located behind the first row can’t operate smoothly, causing their electricity output to fluctuate. In addition, the turbulence makes the turbines vibrate, which accelerates the process of wear and tear. A wind turbine is designed to operate for about 20 years. If it can run longer than that, the wind farm can supply more energy without requiring any additional investment.

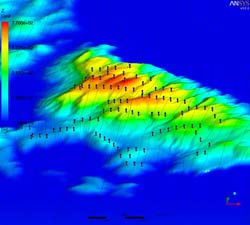

Researchers at Siemens Corporate Technology have now developed a computer model that simulates entire wind farms. Using measurements of wind and rotor speeds, temperature, and turbine output, the software calculates airflows and determines the behavior of all of the turbines, enabling it to set the parameters for operating the wind turbines with as little turbulence as possible. The turbines’ output is adjusted by means of the generators and the angle of the rotor blades. To make this possible, all of the turbines are connected to a central control system via optical fiber lines. Even though the system reduces the output of individual wind turbines, it increases the yield of the wind farm as a whole and ensures that turbines located farther back are subjected to less strain. Operators can use the program to optimize either the energy yield or the service life. Alternatively, they can use it to optimally balance both of these parameters with each other.

Siemens Wind Power has been testing the software in Lillgrund for the past two years. In the fall the model will be optimized on the basis of the collected measurement data, to be followed by a pilot phase. Offshore wind farms are part of Siemens’ environmental portfolio, with which the company generated about €28 billion in sales in fiscal year 2010.

Media Contact

More Information:

http://www.siemens.com/researchnewsAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…