Clay key to high-temperature supercapacitors

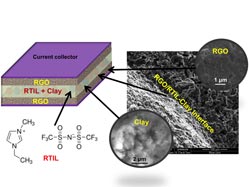

A composite of clay and an electrolyte allowed Rice University researchers to make sheets of material that can serve as both electrolyte and a separator in a new kind of high-temperature supercapacitor. (Credit: Ajayan Group/Rice University)<br>

Clay, an abundant and cheap natural material, is a key ingredient in a supercapacitor that can operate at very high temperatures, according to Rice University researchers who have developed such a device.

The Rice group of materials scientist Pulickel Ajayan reported today in Nature’s online journal, Scientific Reports, that the supercapacitor is reliable at temperatures of up to 200 degrees Celsius (392 degrees Fahrenheit) and possibly beyond. It could be useful for powering devices for use in extreme environments, such as oil drilling, the military and space.

“Our intention is to completely move away from conventional liquid or gel-type electrolytes, which have been limited to low-temperature operation of electrochemical devices,” said Arava Leela Mohana Reddy, lead author and a former research scientist at Rice.

“We found that a clay-based membrane electrolyte is a game-changing breakthrough that overcomes one of the key limitations of high-temperature operation of electrochemical energy devices,” Reddy said. “By allowing safe operation over a wide range of temperatures without compromising on high energy, power and cycle life, we believe we can dramatically enhance or even eliminate the need for expensive thermal management systems.”

A supercapacitor combines the best qualities of capacitors that charge in seconds and discharge energy in a burst and rechargeable batteries that charge slowly but release energy on demand over time. The ideal supercapacitor would charge quickly, store energy and release it as needed.

“Researchers have been trying for years to make energy storage devices like batteries and supercapacitors that work reliably in high-temperature environments, but this has been challenging, given the traditional materials used to build these devices,” Ajayan said.

In particular, researchers have struggled to find an electrolyte, which conducts ions between a battery’s electrodes, that won’t break down when the heat is on. Another issue has been finding a separator that won’t shrink at high temperatures and lead to short circuits. (The separator keeps the electrolyte on the anode and cathode sides of a traditional battery apart while allowing ions to pass through).

“Our innovation has been to identify an unconventional electrolyte/separator system that remains stable at high temperatures,” Ajayan said.

The Rice researchers led by Reddy and Rachel Borges solved both problems at once. First, they investigated using room-temperature ionic liquids (RTILs) developed in 2009 by European and Australian researchers. RTILs show low conductivity at room temperature but become less viscous and more conductive when heated.

Clay has high thermal stability, high sorption capacity, a large active surface area and high permeability, Reddy said, and is commonly used in muds for oil drilling, in modern construction, in medical applications and as a binder by iron and steel foundries.

After combining equal amounts of RTIL and naturally occurring Bentonite clay into a composite paste, the researchers sandwiched it between layers of reduced graphene oxide and two current collectors to form a supercapacitor. Tests and subsequent electron microscope images of the device showed no change in the materials after heating it to 200 degrees Celsius. In fact, Reddy said, there was very little change in the material up to 300 degrees Celsius.

“The ionic conductivity increases almost linearly until the material reaches 180 degrees, and then saturates at 200,” he said.

Despite a slight drop in capacity observed in the initial charge/discharge cycles, the supercapacitors were stable through 10,000 test cycles. Both energy and power density improved by two orders of magnitude as the operating temperature increased from room temperature to 200 degrees Celsius, the researchers found.

The team took its discovery a step further and combined the RTIL/clay with a small amount of thermoplastic polyurethane to form a membrane sheet that can be cut into various shapes and sizes, which allows design flexibility for devices.

Co-authors of the paper are graduate students Marco-Tulio Rodrigues and Hemtej Gullapalli and former postdoctoral researcher Kaushik Balakrishnan, all of Rice; and Glaura Silva, an associate professor at the Federal University of Minas Gerais, Belo Horizonte, Brazil. Ajayan is the Benjamin M. and Mary Greenwood Anderson Professor in Mechanical Engineering and Materials Science and of chemistry at Rice. Borges is a visiting student from the Federal University of Minas Gerais. Reddy is now an assistant professor at Wayne State University in Detroit.

The Advanced Energy Consortium supported the research.

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,708 undergraduates and 2,374 graduate students, Rice’s undergraduate student-to-faculty ratio is 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice has been ranked No. 1 for best quality of life multiple times by the Princeton Review and No. 2 for “best value” among private universities by Kiplinger’s Personal Finance. To read “What they’re saying about Rice,” go to http://tinyurl.com/AboutRiceU.

If you do not wish to receive news releases from Rice University, reply to this email and write “unsubscribe” in the subject line. Office of News and Media Relations – MS 300, Rice University, 6100 Main St., Houston, TX 77005

Media Contact

More Information:

http://www.nature.com/srep/2013/130903/srep02572/full/srep02572.htmlAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…