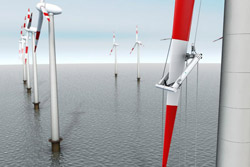

A Robot Inspects Wind Energy Converters

It appears reliably and appears alone. Nimbly and quickly, it pulls itself up a rope meter for meter until it reaches a wind energy converter’s giant rotor blades. Then it goes to work. It thoroughly inspects every centimeter of the rotor blades’ surface. Nothing escapes it. It registers any crack and any delamination in the material and relays their exact positions. In this job, a robot is superior to humans.

The researchers at the Fraunhofer Institute for Factory Operation and Automation IFF are experts in robotics – regardless of whether to clean facades, inspect sewer lines or assist humans. Their latest helper is RIWEA, a robot that inspects the rotor blades of wind energy converters. Primarily made of glass fiber reinforced plastics, rotor blades have to withstand a great deal: wind, inertial forces, erosion, etc. Until now, humans have inspected wind energy converters at regular intervals – not an easy job.

After all, the technicians must closely examine large surfaces – a rotor blade can be up to 60 meters long – in airy heights. “Our robot is not just a good climber,” says Dr. Norbert Elkmann, Project Manager am Fraunhofer IFF and coordinator of the joint project. “It is equipped with a number of advanced sensor systems. This enables it to inspect rotor blades closely.” Are there cracks in the surface? Are the bonded joints and laminations in order? Is the bond with the central strut damaged?

The inspection system consists of three elements: An infrared radiator conducts heat to the surface of the rotor blades. A high-resolution thermal camera records the temperature pattern and thus registers flaws in the material. In addition, an ultrasonic system and a high resolution camera are also on board, thus enabling the robot to also detect damage that would remain hidden to the human eye. A specially developed carrier system ensures that the inspection robot is guided securely and precisely along the surface of a rotor blade.

“It is a highly complex platform with sixteen degrees of freedom, which can autonomously pull itself up ropes,” explains Elkmann. The advantage of this system: It can perform its job on any wind energy converter – regardlesss of whether it is large or small, on land or offshore. The robot always delivers an exact log of the rotor blades’ condition, keeping humans safe and not missing any damage.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…

Innovative microscopy demystifies metabolism of Alzheimer’s

Researchers at UC San Diego have deployed state-of-the art imaging techniques to discover the metabolism driving Alzheimer’s disease; results suggest new treatment strategies. Alzheimer’s disease causes significant problems with memory,…

A cause of immunodeficiency identified

After stroke and heart attack: Every year, between 250,000 and 300,000 people in Germany suffer from a stroke or heart attack. These patients suffer immune disturbances and are very frequently…