A Nano-Tool for Designing the Next Big Battery

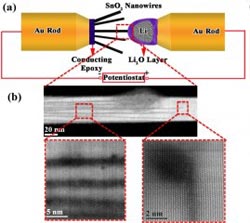

Reza Shahbazian-Yassar<br><br>Michigan Tech's Reza Shahbazian-Yassar has developed a device that allows scientists to watch lithium ions at work inside a battery, opening the door to better designs and materials. Above, (a), the nanobattery setup inside the aberration corrected scanning transmission electron microscope. Below, (b), atomic resolution imaging of the front line of lithium ions entering a tin oxide nanowire. The atomic resolution images show the parallel lithium-ion channels and the formation of dislocations at the tip of the channels.<br>

“You might get seven or eight hours out of your iPhone on one charge, maybe a day,” says Reza Shahbazian-Yassar, an associate professor of mechanical engineering at Michigan Technological University. “This is not enough for many of us. A fully electric car, like the Nissan Leaf, can go up to 100 miles on a single charge. To appeal to a mass market, it should be about 300 miles. We want to increase the power of these systems.”

To wring more power out of lithium ion batteries, scientists are experimenting with different materials and designs. However, the important action in a battery occurs at the atomic level, and it’s been virtually impossible to find out exactly what’s happening at such a scale. Now, Yassar has developed a device that allows researchers to eavesdrop on individual lithium ions—and potentially develop the next generation of batteries.

Batteries are pretty simple. They have three major components: an anode, a cathode and electrolyte between the two. In lithium batteries, lithium ions travel back and forth between the anode and cathode as the battery discharges and is charged up again. The anodes of lithium-ion batteries are usually made of graphite, but scientists are testing other materials to see if they can last longer.

“As soon as lithium moves into an electrode, it stresses the material, eventually resulting in failure,” said Yassar. “That’s why many of these materials may be able to hold lots of lithium, but they end up breaking down quickly.

“If we were able to observe these changes in the host electrode, particularly at the very early stage of charging, we could come up with strategies to fix that problem.”

Ten years ago, observing light elements such as lithium or hydrogen at the atomic level would have been out of the question. Now, however, it’s possible to see light atoms with an aberration corrected scanning transmission electron microscope (AC-STEM). Yassar’s team was able to use one courtesy of the University of Illinois at Chicago, where he is a visiting associate professor.

To determine how the host electrode changes as lithium ions enter it, the team built a nano-battery within the AC-STEM microscope using a promising new electrode material, tin oxide, or SnO2. Then, they watched it charge.

“We wanted to monitor the changes in the tin oxide at the very frontier of lithium-ion movement within the SnO2 electrode, and we did,” Yassar said. “We were able to observe how the individual lithium ions enter the electrode.”

The lithium ions moved along specific channels as they flowed into the tin oxide crystals instead of randomly walking into the host atoms. Based on that data, the researchers were able to calculate the strain the ions were placing on the electrodes.

The discovery has prompted inquiries from industries and national labs interested in using his atomic-resolution capability in their own battery-development work.

“It’s very exciting,” Yassar said. “There are so many options for electrodes, and now we have this new tool that can tell us exactly what’s happening with them. Before, we couldn’t see what was going on; we were just guessing.”

The work was supported by the National Science Foundation and the American Chemical Society Petroleum Research Fund.

An article on the research, “Atomic Scale Observation of Lithiation Reaction Front in Nanoscale SnO2 Materials,” was published online June 3 in ACS Nano. In addition to Yassar, the coauthors are mechanical engineering graduate student Hasti Asayesh-Ardakani and research associate Anmin Nie of Michigan Tech; Li-Yong Gan, Yingchun Cheng and Udo Schwingeschlogl of King Abdullah University of Science and Technology, Saudi Arabia; Qianquin Li, Cezhou Dong and Tao Wang of Zhejiang University, China; and Farzad Mashayek and Robert Klie of the University of Illinois at Chicago.

Media Contact

More Information:

http://www.mtu.eduAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Peptides on Interstellar Ice

A research team led by Dr Serge Krasnokutski from the Astrophysics Laboratory at the Max Planck Institute for Astronomy at the University of Jena had already demonstrated that simple peptides…

A new look at the consequences of light pollution

GAME 2024 begins its experiments in eight countries. Can artificial light at night harm marine algae and impair their important functions for coastal ecosystems? This year’s project of the training…

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…