3-dimensional Light Emitting Diodes for future lighting technologies

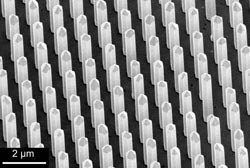

Scanning electron microscopy image of 3D GaN pillars with an aspect ratio (height to width) of 10 as carcass of 3D LEDs. IHT - TU Braunschweig<br>

The innovative 3-dimensional assembly of the diodes is expected to provide more than tenfold the quantity of light output in comparison to those planar LEDs currently in use. The financial grant for this project amounts to a total sum of 3.8 million Euro, whereas the share of the TU Braunschweig amounts to 1.2 million Euro.

Already now, modern high-performance LEDs provide a bright light output at high efficiency and are meanwhile applied for automobile headlights, for example. At present, the production process for these kinds of LEDs is still not cost efficient enough and also the efficiency of these LEDs needs further improvement.

Tiny 'lighthouses' are more efficient

The international team of the GECCO project with their partners from Madrid, Bristol, Lodz, the OSRAM AG Munich and the OSRAM OS GmbH Regensburg is working hard on achieving their ambitious objectives.

Up to now, LEDs are being constructed in a planar way, meaning in layers and completely flat. The more light is being required, the more wafer area has to be produced, which is an expensive and laborious approach. The exceptional idea of the GECCO project is to assemble LEDs in a three-dimensional way so that actually every LED consists of a ‘light emitting tower’ from which the entire vertical surface is emitting light. Obviously the surface of the tower is much larger compared to the ground area of a planar LED. And in fact, it is exactly the gain of light emitting area that leads to a higher light output.

Thus, the manufacturing of an LED becomes much more cost-effective and as a result replacing ancient electric bulbs, halogen lamps as well as energy saving bulbs to LEDs is getting a lot more profitable. Considering the fact that currently 20 % of electrical energy worldwide is being utilized for illumination, this innovation provides an enormous potential as far as cost-effectiveness is concerned. In addition, LED lighting is particularly important for future electric mobility. Energy saving is of utmost importance in electric cars.

A million LEDs per square millimeter

The dimensions of the ‘light emitting towers’ are within the micrometer range. This means approximately one million LEDs fit on an area of one square millimeter. This process requires utmost precision which can only be achieved by applying nanotechnology manufacturing techniques.

The GECCO project is coordinated by Prof. Andreas Waag from the Institute of Semiconductor Technology, which is part of the Electrical Engineering Department of the Technische Universität Braunschweig.

With this project the Faculty of Electrical Engineering, Information Technology, Physics sets another example as to the further and ongoing strengthening of the University’s research profile in the specialization of NanoSystemsEngineering – this time in the true sense of the word – a bright and shining sign.

Background

The Institute of Semiconductor (IHT) is an institution of the Technische Universität Braunschweig and belongs to the Faculty of Electrical Engineering, Information Technology, Physics. The institute and its 40 staff members are engaged in particular in the research of semiconductor nanostructures and their application among others for nanoLEDs, the hydrogen generation, gas sensors, thermoelectrical generators, high-temperature and nanoparticle-sensors as well as solar cells.

For further information, please contact:

Prof. Dr. Andreas Waag

Institute of Semiconductor Technology

Technische Universität Braunschweig

Hans-Sommer-Strasse 66

38106 Braunschweig

Germany

a.waag@tu-braunschweig.de

phone +49-531-391-3774 (secretary) or -3773

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…

Mobility of the future, quantum technologies, space travel, transfer

The University of Stuttgart at Hannover Messe ’24. From sustainable mobility to quantum technologies and their potential: The University of Stuttgart will be showcasing exciting research projects, pioneering solutions, and…

Culinary pleasure meets innovative cutting-edge research

CeTI Cluster of Excellence at TU Dresden opens “robot kitchen”. April 15, 2024, the Cluster of Excellence Centre for Tactile Internet with Human-in-the-Loop (CeTI) at TUD Dresden University of Technology…