No-power Wi-Fi connectivity could fuel Internet of Things reality

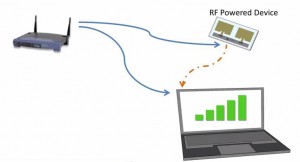

Wi-Fi backscatter uses radio frequency signals as a power source and reuses existing Wi-Fi infrastructure to provide Internet connectivity to battery-free devices.

This not-so-distant “Internet of Things” reality would extend connectivity to perhaps billions of devices. Sensors could be embedded in everyday objects to help monitor and track everything from the structural safety of bridges to the health of your heart. But having a way to cheaply power and connect these devices to the Internet has kept this from taking off.

Now, University of Washington engineers have designed a new communication system that uses radio frequency signals as a power source and reuses existing Wi-Fi infrastructure to provide Internet connectivity to these devices. Called Wi-Fi backscatter, this technology is the first that can connect battery-free devices to Wi-Fi infrastructure.

“If Internet of Things devices are going to take off, we must provide connectivity to the potentially billions of battery-free devices that will be embedded in everyday objects,” said Shyam Gollakota, a UW assistant professor of computer science and engineering. “We now have the ability to enable Wi-Fi connectivity for devices while consuming orders of magnitude less power than what Wi-Fi typically requires.”

The researchers will publish their results at the Association for Computing Machinery’s Special Interest Group on Data Communication‘s annual conference this month in Chicago. The team also plans to start a company based on the technology.

This work builds upon previous research that showed how low-powered devices such as temperature sensors or wearable technology could run without batteries or cords by harnessing energy from existing radio, TV and wireless signals in the air. This work takes that a step further by connecting each individual device to the Internet, which previously wasn’t possible.

The challenge in providing Wi-Fi connectivity to these devices is that conventional, low-power Wi-Fi consumes three to four orders of magnitude more power than can be harvested in these wireless signals. The researchers instead developed an ultra-low power tag prototype with an antenna and circuitry that can talk to Wi-Fi-enabled laptops or smartphones while consuming negligible power.

These tags work by essentially “looking” for Wi-Fi signals moving between the router and a laptop or smartphone. They encode data by either reflecting or not reflecting the Wi-Fi router’s signals, slightly changing the wireless signal. Wi-Fi-enabled devices like laptops and smartphones would detect these minute changes and receive data from the tag.

In this way, your smart watch could download emails or offload your workout data onto a Google spreadsheet.

“You might think, how could this possibly work when you have a low-power device making such a tiny change in the wireless signal? But the point is, if you’re looking for specific patterns, you can find it among all the other Wi-Fi reflections in an environment,” said co-author Joshua Smith, a UW associate professor of computer science and engineering and of electrical engineering.

The UW’s Wi-Fi backscatter tag has communicated with a Wi-Fi device at rates of 1 kilobit per second with about 2 meters between the devices. They plan to extend the range to about 20 meters and have patents filed on the technology.

Other co-authors include David Wetherall, a UW professor of computer science and engineering; and Bryce Kellogg and Aaron Parks, both doctoral students in electrical engineering.

The research was funded by the UW Commercialization Gap Fund, the Qualcomm Innovation Fellowship, Washington Research Foundation, the National Science Foundation and the UW.

###

For more information, contact the research team at iotwifi@cs.washington.edu

Media Contact

All latest news from the category: Communications Media

Engineering and research-driven innovations in the field of communications are addressed here, in addition to business developments in the field of media-wide communications.

innovations-report offers informative reports and articles related to interactive media, media management, digital television, E-business, online advertising and information and communications technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…