New ORNL Electric Vehicle Technology Packs More Punch in Smaller Package

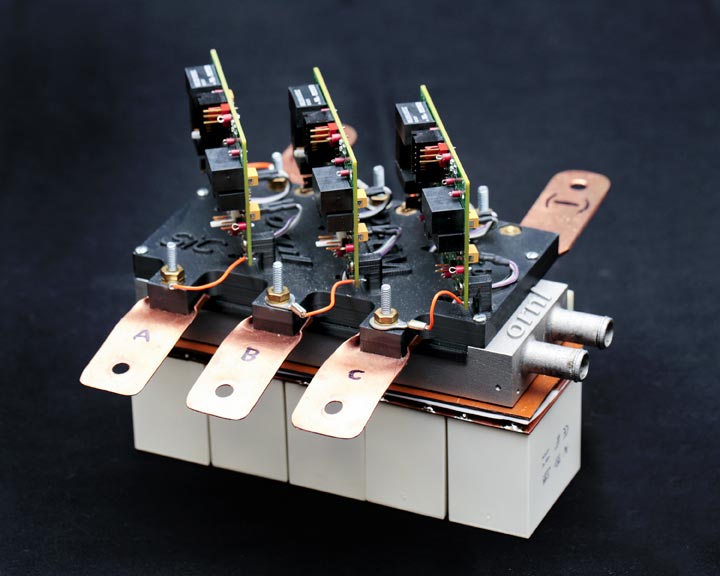

ORNL's 30-kilowatt power inverter offers greater reliability and power in a compact package. Source: ORNL

Using 3-D printing and novel semiconductors, researchers at the Department of Energy’s Oak Ridge National Laboratory have created a power inverter that could make electric vehicles lighter, more powerful and more efficient.

At the core of this development is wide bandgap material made of silicon carbide with qualities superior to standard semiconductor materials. Power inverters convert direct current into the alternating current that powers the vehicle. The Oak Ridge inverter achieves much higher power density with a significant reduction in weight and volume.

“Wide bandgap technology enables devices to perform more efficiently at a greater range of temperatures than conventional semiconductor materials,” said ORNL’s Madhu Chinthavali, who led the Power Electronics and Electric Machinery Group on this project. “This is especially useful in a power inverter, which is the heart of an electric vehicle.”

Specific advantages of wide bandgap devices include: higher inherent reliability; higher overall efficiency; higher frequency operation; higher temperature capability and tolerance; lighter weight, enabling more compact systems; and higher power density.

Additive manufacturing helped researchers explore complex geometries, increase power densities, and reduce weight and waste while building ORNL’s 30-kilowatt prototype inverter.

“With additive manufacturing, complexity is basically free, so any shape or grouping of shapes can be imagined and modeled for performance,” Chinthavali said. “We’re very excited about where we see this research headed.”

Using additive manufacturing, researchers optimized the inverter’s heat sink, allowing for better heat transfer throughout the unit. This construction technique allowed them to place lower-temperature components close to the high-temperature devices, further reducing the electrical losses and reducing the volume and mass of the package.

Another key to the success is a design that incorporates several small capacitors connected in parallel to ensure better cooling and lower cost compared to fewer, larger and more expensive “brick type” capacitors.

The research group’s first prototype, a liquid-cooled all-silicon carbide traction drive inverter, features 50 percent printed parts. Initial evaluations confirmed an efficiency of nearly 99 percent, surpassing DOE’s power electronics target and setting the stage for building an inverter using entirely additive manufacturing techniques.

Building on the success of this prototype, researchers are working on an inverter with an even greater percentage of 3-D printed parts that’s half the size of inverters in commercially available vehicles. Chinthavali, encouraged by the team’s results, envisions an inverter with four times the power density of their prototype.

Others involved in this work, which was to be presented today at the Second Institute of Electrical and Electronics Engineers Workshop on Wide Bandgap Power Devices and Applications in Knoxville, were Curt Ayers, Steven Campbell, Randy Wiles and Burak Ozpineci.

Research for this project was conducted at ORNL’s National Transportation Research Center and Manufacturing Demonstration Facility, DOE user facilities, with funding from DOE’s Office of Energy Efficiency and Renewable Energy.

UT-Battelle manages ORNL for the Department of Energy's Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit http://science.energy.gov/.

Contact Information

Ron Walli

Oak Ridge National Laboratory

Communications

(865) 576-0226; wallira@ornl.gov

Media Contact

All latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…