Nanocomposites toughen up

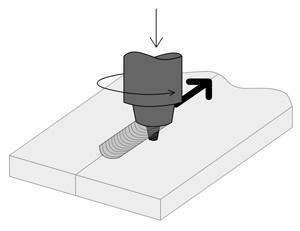

Schematic diagram of friction stir processing, a method used to improve the hardness and tensile strength of aluminum-based nanocomposites. Copyright : © 2014 A*STAR Singapore Institute of Manufacturing Technology

One challenge in producing strong, elastic and hard-wearing nanocomposites is obtaining an even distribution of the nanoparticles in the metal matrix. Now, researchers at A*STAR have used a process known as friction stir processing (see image) to produce an evenly distributed mix of nanosized aluminum oxide (Al2O3) particles in aluminum1. Their technique is a viable new method for manufacturing nanocomposites and has exciting potential for the car, space and defense industries.

“Current powder metallurgy or liquid processing methods fail to achieve uniform processing,” says research leader Junfeng Guo, who is from the A*STAR Singapore Institute of Manufacturing Technology.

Guo’s team drilled hundreds of 1-millimeter-diameter holes into the surface of a thin sheet of an aluminum alloy. They then injected a slurry of aluminum oxide nanoparticles into the holes and heated the sheet in an oven. After cooling the sheet, the team plunged a rotating tool into it — this is the friction stir processing step. The friction generated between the tool and the sheet caused the material to plasticize. The tool was moved around to ensure that the entire sheet was plasticized.

Placing the nanoparticles in the sheet prior to the friction stir processing step significantly increased the concentration of nanoparticles in the composite. “It also reduced the amount of airborne particles produced during powder placement and friction stir processing,” explains Guo.

The team used scanning electron microscopy to check two key properties that influence the strength of nanocomposites. They first demonstrated that the nanoparticles were uniformly dispersed, which means the material has no weak points. They also found that the grains or crystals of the aluminum matrix that recrystallized after being plasticized were extremely small; smaller aluminum matrix grains can flow past each other more smoothly than larger particles, enhancing the strength of the material.

By measuring the grain size after performing friction stir processing with and without the Al2O3 nanoparticles, the team showed that the nanoparticles contributed to the reduction in grain size.

The best nanoparticle distribution and smallest aluminum alloy grains were obtained after passing the rotating tool through the sheet four times. The team then demonstrated that the composite made in this way had significantly improved hardness and tensile strength compared to untreated aluminum alloy sheets.

“We plan to continue this research to further improve the mechanical and thermal properties as well as the wear resistance of the nanocomposites,” says Guo. “Eventually, we aim to commercialize our technology to aid local industry.”

Reference:

Guo, J. F., Liu, J., Sun, C. N., Maleksaeedi, S., Bi, G. et al. Effects of nano-Al2O3 particle addition on grain structure evolution and mechanical behaviour of friction-stir-processed Al. Materials Science and Engineering: A 602, 143–149 (2014) |

Associated links

Media Contact

More Information:

http://www.researchsea.comAll latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…