New high-performance steel with potential applications in the automotive industry

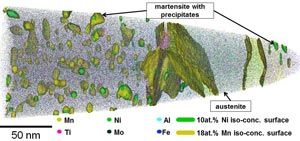

<br>Result of an analysis by the 3D-atom probe. The martensitic and austenitic phases are visible. Even single atoms are recognized by this technique – each dot represents the location of one atom while the surfaces are regions of iso-concentration of a certain element. Quelle: MPIE<br>

The requirements for steels applied in the automotive industry are manifold: strong steels are used for centre pillars, the part of a car installed next to the driver’s door. On the other hand, the front part of a car must consist of strong and at the same time ductile material.

Thus, in case of a crash, the shock energy can be absorbed and the driver is protected. Dr. Dirk Ponge, group leader at the MPIE, has achieved to combine both requirements in one class of new steel, named “lean maraging TRIP steels”. Due to a high nickel content conventional maraging steels are very strong and used in air plane landing gear. The term maraging merges ‘martensite’ and ‘aging’.

The name is derived from a special heat treatment (aging) which strengthens an already quite strong martensite structure. ”The use of a high amount of nickel results in a strong steel, but also caused an expensive production.” That’s why Ponge reduced the nickel content and found a surprising effect.

Combination of strength and ductility

During heat treatment, the formation of intermetallic precipitations causes an increase in strength. At the same time austenite is formed which is the reason for the increase in ductility and the basis for a second effect: the TRIP effect. TRIP stands for transformation induced plasticity. Triggered by a deformation process, a phase transformation from metastable austenite to martensite takes place in the material. This leads to an increase in strain hardening rate and enables to reach high elongations. With both these effects occurring, one obtains a good combination of tensile strength and total elongation up to 30.000 MPa%. The intermetallic precipitations, which are responsible for the excellent properties are analysed with the 3-dimensional atom probe.

Optimisation by computational materials design

Currently, the development of these steels is being optimised. Ponge expects to further decrease the production costs and to improve the mechanical properties by modifying the alloy composition. This is performed in close cooperation with the department of Computational Materials Design. The department of Prof. Jörg Neugebauer is calculating with the means of quantum physics, which precipitations are formed in the material with respect to the composition. This improves the efficiency of the further development and reduces the number of experiments. A systematic and application-oriented development of the lean high-performance steels is on the way.

Yasmin A. Salem, M.A.

Public Relations

Max-Planck-Institut für Eisenforschung GmbH

Max-Planck-Str. 1

40237 Düsseldorf

Germany

phone: +49 (0)211 6792 722

fax: +49 (0)211 6792 218

Media Contact

More Information:

http://www.mpie.deAll latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…